Understanding the Classes of Hi Vis Clothing: Class 1, Class 2, and Class 3

The right class of hi vis clothing needs to be selected by employers to ensure worker safety in hazardous environments. Hi vis clothing falls into three classes within the EN ISO 20471 standard based on the level of visibility they offer, which depends on the amount of fluorescent fabric and reflective tape on the garment.

The different categories of hi vis clothing - Class 1, Class 2, and Class 3 - will be covered in this article, along with suggestions on which class is appropriate for your workforce. We'll also discuss how adding your company's branding can be done and how customised printing can impact compliance.

- Page Contents

- What is EN ISO 20471?

- The Different Classes of Hi Vis Clothing

- How to Determine the Class of a Hi Vis Garment

- How Does Custom Printing Affect Hi Vis Compliance?

- Ensuring Your Workers are Wearing the Right Class of Hi Vis

- Conclusion: The Right Hi Vis Class Can Save Lives

What is EN ISO 20471?

EN ISO 20471 is the European standard that governs high visibility clothing in the UK. It ensures that hi vis garments is manufactured to keep the wearer visible in both bright and dim light. The minimum amount of fluorescent fabric and retro-reflective tape required to make the wearer visible from all sides is laid out in the standard.

Hi vis clothing is particularly important in industries like construction, engineering, and logistics, where there’s a high risk of accidents involving moving vehicles or heavy machinery. Wearing the right class of hi vis clothing can significantly reduce the risk of accidents, especially in low-light conditions or where workers are near fast-moving vehicles.

The Different Classes of Hi Vis Clothing

The EN ISO 20471 standard divides hi vis clothing into three classes. Each class is designed for different levels of risk, and the classification is based on the amount of visible fluorescent and reflective material.

Class 1: The Lowest Level of Visibility

Class 1 hi vis clothing provides the lowest level of visibility and is only suitable for lower-risk environments. This type of clothing is typically worn in areas where there’s less vehicle movement and minimal risk from heavy machinery.

Class 1 garments are required to have at least:

- 0.14 m² of fluorescent material (such as yellow or orange fabric).

- 0.10 m² of retro-reflective material (the reflective strips).

Examples of Class 1 clothing include:

- High-visibility trousers without a suitable high-visibility top.

- Hi vis vests without sleeves that have a small amount of reflective tape on them.

When to wear Class 1 garments: Class 1 clothing is appropriate for places such as inside warehouses or low-traffic areas where employees are kept apart from moving machinery or vehicles. Because the coverage is limited, it is usually not advised for tasks performed outdoors or in locations where there are considerable hazards.

Class 2: The Intermediate Level of Visibility

Class 2 hi vis clothing offers an intermediate level of visibility and is required in environments where there’s moderate risk from moving vehicles, forklifts, or machinery. Road workers and those working near traffic often wear Class 2 hi vis clothing.

Class 2 garments must have:

- 0.50 m² of fluorescent material.

- 0.13 m² of retro-reflective material.

Examples of Class 2 clothing include:

- Standard sleeveless hi-vis t shirts with two horizontal reflective bands.

- Hi Vis Bodywarmers or Jackets without full-length sleeves.

When to wear Class 2 garments: Workers in environments such as building sites, road construction sites, and locations with heavy vehicle traffic require Class 2 hi vis clothing. This reduces the likelihood of accidents by ensuring that workers can be seen from a distance in low light.

Class 3: The Highest Level of Visibility

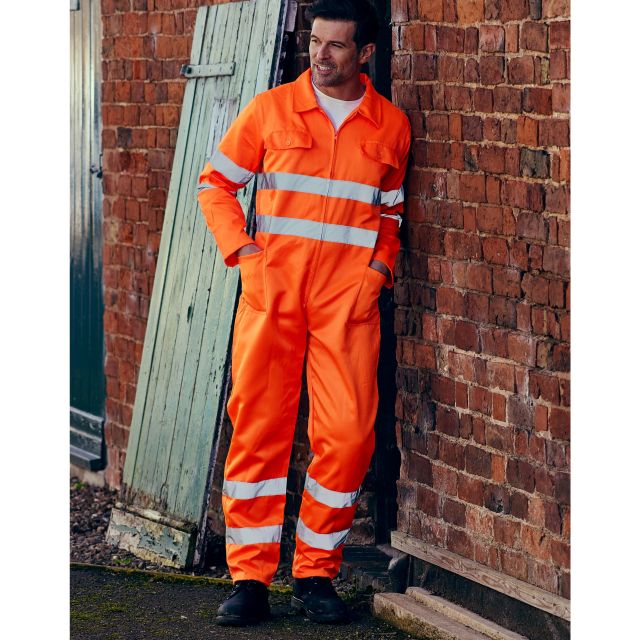

Class 3 hi vis clothing provides the highest level of visibility and is essential in environments where workers are at high risk, such as motorways, railway lines, or areas where fast-moving vehicles are present.

Class 3 garments require:

- 0.80 m² of fluorescent material.

- 0.20 m² of retro-reflective material.

Class 3 garments must cover the torso and include long sleeves or trousers. They must have reflective tape across the body, arms, and/or legs to ensure full visibility from all angles.

Examples of Class 3 clothing include:

- Hi vis jackets with full-length sleeves and reflective tape on both the torso and sleeves.

- Hi vis trousers combined with a long-sleeved hi vis jacket to meet the surface area requirements.

When to wear Class 3 clothing: Class 3 clothing is necessary for workers in hazardous workplace environments such as on highways, railways, and construction sites with heavy traffic. These garments give the maximum protection, ensuring that workers are visible from a distance and from all angles, especially in low-light conditions or high-speed settings.

How to Determine the Class of a Hi Vis Garment

The class of a garment is indicated on the label of any EN ISO 20471 compliant hi vis clothing. You should see the EN ISO 20471 icon along with the corresponding class number on this label, providing a clear indication of the level of visibility the garment offers. The example label pictured shows Class 2:

Determining which class of hi vis clothing is needed for your specific working conditions requires a thorough risk assessment. The appropriate class will depend on the level of risk present in the work environment, influencing the amount of fluorescent material and reflective tape needed for adequate visibility.

Only by evaluating the specific hazards your workers face, you can select the right class to ensure their safety.

How Does Custom Printing Affect Hi Vis Compliance?

While adding your company’s logo to hi vis clothing is a great way to promote your brand and make workers easily identifiable, it’s important to ensure that custom printing doesn’t reduce the garment’s visibility and make it non-compliant with EN ISO 20471.

The Impact of Large Logos

A large logo printed onto hi vis clothing reduces the area of visible fluorescent material. This can potentially make the garment fall below the required minimum surface area for compliance. For example:

A Class 2 vest requires 0.50 m² of fluorescent fabric. If the garment offers that as a maximum, and a large logo covers 0.10 m², you’re left with only 0.40 m² of visible material. The addition of the logo means the finished garment no longer meets the minimum standard.

To avoid this, consider placing logos in non-critical areas, such as contrast panels or alter your logo so it doesn’t interfere with the required visibility.

Balancing Branding with Safety

It’s essential to balance the need for branding with safety compliance. When you work with a BSIF registered supplier like XAMAX®, you can be sure your custom logos won’t compromise the safety of your workforce. We understand the importance of both branding and compliance, and we can help you position your logo in a way that maintains the garment’s visibility while still promoting your business.

For hi vis garments like polo shirts and softshell jackets, you can also consider embroidery as an alternative to printing. Embroidery typically uses a smaller surface area and can be placed strategically to avoid interfering with the fluorescent fabric.

Ensuring Your Workers are Wearing the Right Class of Hi Vis

You need to conduct a thorough risk assessment of the working environment so you choose the right class of hi vis clothing for your team. Consider the level of vehicle movement, the speed of traffic, and the lighting conditions when deciding whether your workers need Class 1, Class 2, or Class 3 hi vis clothing.

- Low-risk environments: Class 1 may be suitable for indoor areas like warehouses, or low-traffic zones.

- Medium-risk environments: Class 2 is ideal for construction sites or areas where vehicles and plant move at slower speeds.

- High-risk environments: Class 3 is required for high-speed zones or areas where there is a high level of danger from moving vehicles or machinery.

At XAMAX®, we specialise in hi vis clothing as well as a complete range of workwear to suit all industries. As a BSIF Registered Supplier, we ensure our products meet the highest safety standards. Explore more on the XAMAX® homepage.

Conclusion: The Right Hi Vis Class Can Save Lives

Understanding the different classes of hi vis clothing is crucial for maintaining workplace safety. Whether your team needs Class 1, Class 2, or Class 3 garments, it’s important to ensure that the clothing provides the right level of visibility for the risks they face.

Make sure your workforce stays visible, safe, and compliant with EN ISO 20471 by working with a trustworthy supplier like XAMAX®. Consider the influence of custom printing on compliance, and you'll have both safety and branding covered.