The safety footwear requirements were considerably updated in 2022, most notably in the EN ISO 20345:2022 and EN ISO 20347:2022 standards. These changes reflect major advances in ensuring worker safety across a variety of sectors. Understanding these developments is critical for employers, organisations, and individuals responsible for workplace safety to maintain compliance and protect employees' well-being.

This article will walk you through the important changes to safety footwear regulations, how they affect both employers and employees, and how to make sure your footwear meets the most recent standards.

- Page Contents

- Overview of the 2022 Safety Footwear Standards

- Types of Footwear Covered by the 2022 Standards

- Key UK Regulations for Safety Footwear

- Key Changes in EN ISO 20345:2022 and EN ISO 20347:2022

- New Markings and Marking Changes

- How to Ensure Compliance with the New Standards

- Applications by Industry

- Why Choose XAMAX® for Your Safety Footwear?

- Conclusion

Overview of the 2022 Safety Footwear Standards

The EN ISO 20345 and EN ISO 20347 standards are essential to establishing the minimum requirements for safety footwear. They encompass everything from protection features to testing regulations, ensuring that industrial footwear minimises worker injuries.

The EN ISO 20345:2022 standard is largely applicable to footwear designed to provide protection in high-risk areas (such as construction and engineering). EN ISO 20347:2022, on the other hand, focusses on occupational footwear in which high-level protection (such as toe caps) is optional but some protection (such as slip resistance) is necessary.

Here are the most significant modifications in these standards from the previous editions (EN ISO 20345:2011 and EN ISO 20347:2012):

Types of Footwear Covered by the 2022 Standards

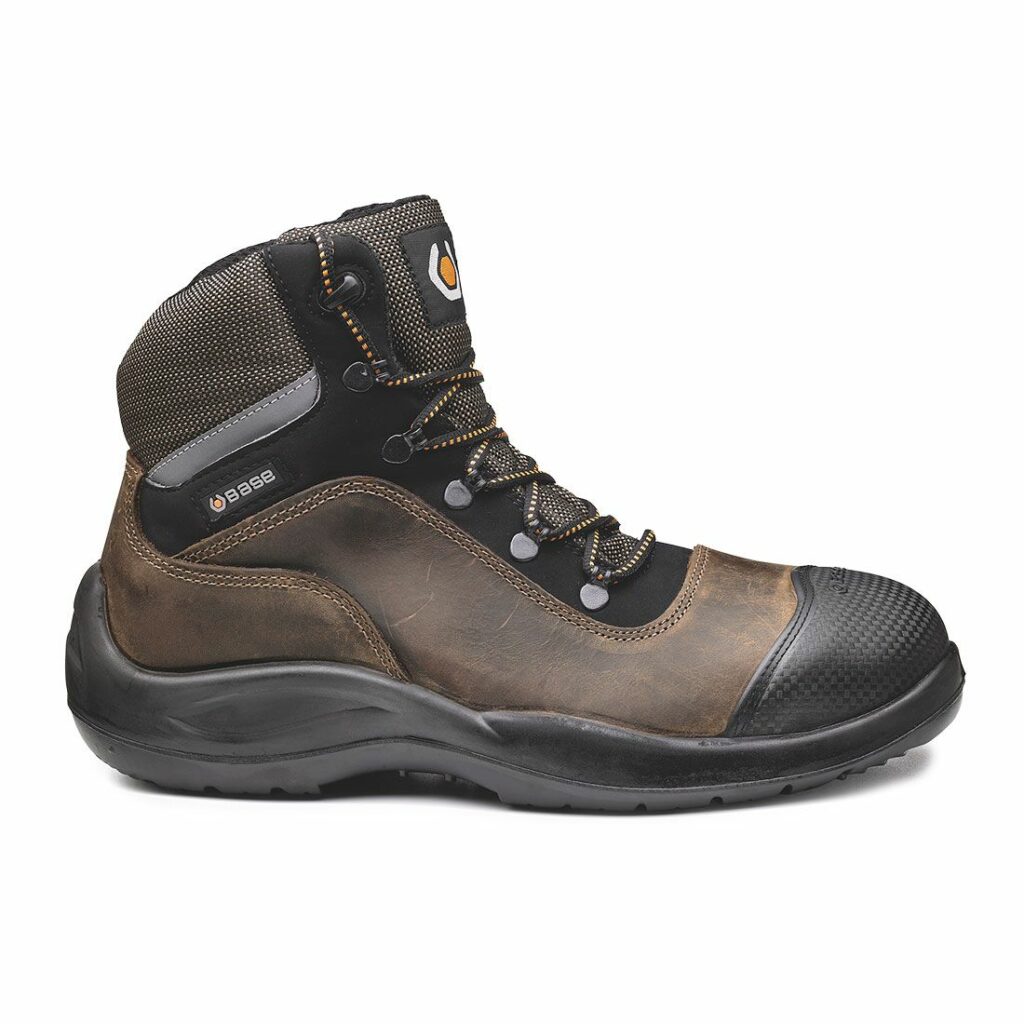

- Safety Boots: Footwear designed for industries with a high risk of impact or compression injuries, such as construction, manufacturing, and mining.

- Safety Shoes: Typically used in lower-risk environments like warehousing, these offer toe protection and slip resistance.

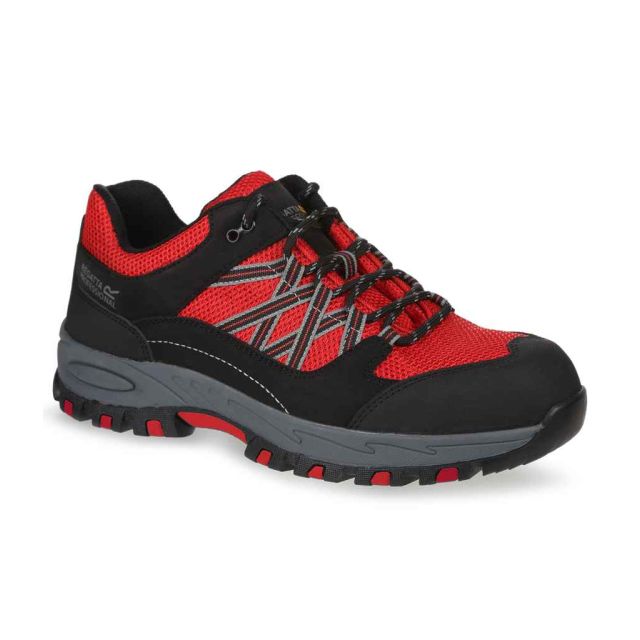

- Safety Trainers: Lightweight footwear ideal for roles where mobility is key, such as in logistics or maintenance.

- Wellington Boots: Provide protection in wet or chemical-heavy environments like agriculture or fisheries, with resistance to liquids and chemicals.

Each type of footwear must meet specific EN ISO 20345:2022 or EN ISO 20347:2022 ratings depending on the work environment.

Key UK Regulations for Safety Footwear

Employers must provide personal protection equipment (PPE) such as safety footwear to employees who are exposed to health or safety dangers, according to UK legislation. Among these are the Personal Protective Equipment at Work Regulations of 1992, which align to European standards and stipulate that employers ensure that PPE is suitable, well-maintained, and provided at no charge when required.

With the 2022 updates, UK safety standards now reflect the following changes in PPE footwear:

Key Changes in EN ISO 20345:2022 and EN ISO 20347:2022

New Classification for Slip Resistance: The new standards provide enhanced guidelines for slip resistance, now a mandatory requirement for all certified footwear. Testing on both ceramic tiles (SRA) and steel plates with glycerol (SRB) is included to simulate various working environments. Footwear must pass tests for both to meet the SRC designation, which applies to all high-slip risk industries.

Breathability and Comfort: Worker comfort has been emphasised in the latest regulations. The EN ISO 20345:2022 standard includes improved guidelines on breathability, moisture management, and overall comfort, making long shifts in safety boots more manageable, reducing fatigue, and increasing worker productivity.

Impact Resistance of Toe Caps: Toe caps must still withstand a 200-Joule impact (equivalent to dropping a 20 kg weight from a height of 1 meter). However, composite toe caps (made from non-metal materials) are now more widely tested under varying temperatures, ensuring that safety boots perform equally well in extreme hot or cold conditions.

Penetration Resistance: Footwear must meet updated penetration resistance standards, ensuring that soles protect against sharp objects in industrial settings. Composite and steel midsole protections must undergo strict testing to prevent penetration by sharp objects like nails, glass, or debris on site. This is particularly relevant for construction and demolition industries.

Electrical and Anti-Static Properties: In high-risk sectors like electronics and energy, regulations for electrical resistance and anti-static properties have been tightened. The new standards now include more stringent tests to ensure footwear protects against electrostatic discharge (ESD) or electrical shocks.

Heat and Cold Resistance: The EN ISO 20345:2022 standard now provides more detailed guidelines on the HI (heat insulation) and CI (cold insulation) ratings, ensuring footwear can withstand a range of environmental conditions. This is especially relevant for industries such as welding, foundries, and outdoor work.

Sustainability and Materials: The 2022 standards emphasise sustainability, encouraging manufacturers to use eco-friendly and recyclable materials while maintaining high levels of protection. This focus is a reflection of the industry's drive towards more sustainable manufacturing practices.

New Markings and Marking Changes

With regulation changes comes new safety claims and new markings to suit the advancements in safety footwear technology:

| Icon | Description |

|---|---|

| FO (Fuel Oil Resistance): This marking indicates that the outsole material has been tested for resistance to fuel oils. This is no longer part of the Shortcut codes and must be marked separatley |

| P (Penetration Resistance) is now split across 3 codes: P - Perforation resistance metallic. Resistance to sole perforation of nails and sharp objects. Incorporating a metallic perforation resistant insert. PL - Perforation resistance non-metallic (LARGE). Resistance to perforation of nails. Incorporating a non-metallic Perforation resistant insert, tested with a 4.5mm test nail. For general end use where nails may be present. PS - Perforation resistance non-metallic (SMALL). Resistance to perforation of nails. Incorporating a non-metallic Perforation resistant insert, tested with a 3mm test nail. Intended for specialist uses where there is a higher likelyhood of encountering nails or likelyhood of encountering narrower nails. |

| C (Partially Conductive). The terminology has been changed from “Conductive”, to prevent confusion with claims associated with live electrical working. |

| SRA, SRB, SRC (Slip Resistance Ratings) are not mandatory. Slip resistance on tiled floor surface with Sodium Lauryl sulphate (soapy water) lubricant, tested at both the heel and forepart. No additional marking is applied. SR - Slip resistance on the tiled floor surface with glycerol lubricant, tested at both the heel and forepart. The steel floor surface is no longer used in testing. Ø - Slip resistance properties have not been achieved but the outsole includes specialist features such as spikes for logging or heavy cleats for use in soft and loose ground. |

| WPA (Water Resistance): Formerly "WRU" indicates that the footwear has water-resistant uppers, meaning the material used for the upper part of the footwear can resist water penetration. This feature is important for workers in wet or damp environments, such as those in outdoor construction or maintenance roles, where keeping the feet dry is critical to avoid discomfort and potential health risks such as trench foot. |

| LG - A new safety claim "ladder grip" indicates that the sole is designed with patterning in the waist area to conform to the rungs of a ladder. |

| SC - A new claim "Scuff cap" indicates that the footwear includes an additional overlay material in the toe area offering abrasion resistance during kneeling activities. |

How to Ensure Compliance with the New Standards

Employers should review their current stock of safety footwear and ensure that it complies with the EN ISO 20345:2022 or EN ISO 20347:2022 standards.

Footwear should be inspected regularly for wear and tear, and employees should be trained to understand the importance of choosing footwear based on the specific hazards they face on-site.

Applications by Industry

The updates to these standards are designed to address industry-specific risks:

- Construction: Focus on impact and penetration resistance, ensuring that all footwear meets S3 standards with toe cap protection and penetration resistance.

- Engineering: Higher standards for electrical resistance and protection against sharp objects, with composite and steel options now more rigorously tested.

- Logistics and Warehousing: Emphasis on slip resistance and lightweight comfort, with composite toe caps offering protection without the bulk of steel.

- Agriculture and Fisheries: Increased focus on waterproofing, chemical resistance, and thermal insulation to protect workers in wet environments.

Why Choose XAMAX® for Your Safety Footwear?

As a BSiF Registered Safety Supplier, XAMAX® ensures that every pair of safety footwear we supply complies with the latest UK and European standards. We pride ourselves on providing safety boots, shoes, and trainers that meet or exceed the EN ISO 20345:2022 and EN ISO 20347:2022 standards, so your team gets maximum protection in any work environment.

Whether you need steel toe caps for heavy industry or lightweight composite safety trainers for logistics, we have the perfect solution for your workforce.

Browse our range of compliant safety footwear or contact our team to discuss your PPE needs.

Conclusion

The 2022 updates to safety footwear regulations bring essential changes to protect workers across various industries.

By understanding the requirements of EN ISO 20345:2022 and EN ISO 20347:2022, you can ensure that your safety footwear meets the latest standards, providing maximum protection and comfort.

From improved slip resistance to more stringent electrical safety standards, these updates highlight the importance of choosing the right footwear for the job.

Stay compliant, protect your workers, and choose XAMAX® for all your safety footwear needs.

The safety footwear requirements were considerably updated in 2022, most notably in the EN ISO 20345:2022 and EN ISO 20347:2022 standards. These changes reflect major advances in ensuring worker safety across a variety of sectors. Understanding these developments is critical for employers, organisations, and individuals responsible for workplace safety to maintain compliance and protect employees’ […]

If you are deciding between different types of safety boots or shoes, you might be choosing between composite and steel toe cap options. Here are the differences explained in one short post and some advice on which type is right for you, your budget and your job role.

- Page Contents

- The Difference Between Steel & Composite Protectors

- The Cost Differences

- Choosing The Right Toe Cap

- Why Choose XAMAX® for Your Safety Footwear Needs?

- Conclusion

The Difference Between Composite And Steel Toe Capped Boots Or Safety Boots

There are many different types of protective footwear, but there are only 2 main types of toe protection: Steel and Composite.

Steel toe cap safety boots (and shoes) use a piece of formed steel to protect the wearer's toes. Composite toecapoed boots use a mixture of plastics, carbon fibres and/or rubber. Both can be produced to meet health and safety standards on safety footwear.

Steel options are usually lined on the inside for extra comfort and the steel will be inserted inside the leather of the toe box of the boot or shoe.

A composite safety boot or shoe is a newer invention than the ol' faithful steel toe and it is made using anything except metal.

Both serve the same purpose of protecting your toes from falling heavy objects or errant pieces of machinery.

They both come with different levels of comfort and protection - and therefore price options.

The Cost Differences

There are various price points for both types of safety boot. Depending on the strength and level of protection, the level of comfort, weight and even aesthetic appearance, you can spend anywhere between £15 to £150+ on a pair of protective boots.

The good news is that there are various options to suit all budgets and job roles.

Which Toe-Cap Is Right For Your Job Role

Here are some of the pros and cons of both steel toe-capped and composite toe-capped safety boots.

Make sure not to waste your time getting an unsuitable, heavy rigger boots if you are picking light-to-mid-weight stock in a warehouse.

The next couple of sections will give you all the info you need.

Did you know that even management staff don't need to compromise on safety if they wear smart safety shoes?

Steel Toe Caps

Best for people working with heavy objects but don't need to walk much during a shift.

When it comes to sheer strength of protection, steel toe caps out perform composite options. The protection offered by a well designed steel toe capped boot or safety shoe cannot be beaten.

If you work in a role which does not result in walking miles during a shift, but you do work in a role which sees you handling heavy materials - such as a steel erector or many engineering roles - then steel options are the safety boots for you.

This is because they are heavier than composite safety footwear, but protection from falling weight is their main purpose, as opposed to ease of mobility.

Another thing to note, if you are working outside during the colder months be sure to choose a lined option. Steel is poor at retaining heat so feet will soon become cold.

Also worth mentioning at this point; an old urban myth is that a heavy object could bend the steel toe cap to the point that it could amputate the wearers toes, but this myth has since been busted by the Mythbusters on Episode 42

Composite Toe Cap

Best for those needing to resist electro-static charge or those who cover a good distance of walking during their shift. A pair of composite safety trainers might be even better than a boot or shoe.

Much lighter on your feet than a steel toe cap option, a composite safety shoe will be the choice if you need to walk any sort of distance during a shift.

The trade off for this is that some cheaper composite boots/safety shoes might not reach the highest standards of safety protection. They might only reach the minimum level to be legally classed as safety footwear, but be sure to check they comply with required HSE rules and regulations on footwear protection levels for your job role.

If you are unsure, you should check with your supervisor or employer who needs to be able to ensure you have adequate protection. This is the case even if you are given a company login to purchase your PPE online or will be reimbursed for your expense.

Why Choose XAMAX® for Your Safety Footwear Needs?

XAMAX® understands the importance of getting the right safety footwear for your specific job role, which is why we offer a wide selection of both steel toe and composite toe cap options.

We’re a BSIF registered safety supplier, so you can trust us to provide safety footwear that meets the highest standards.

Our selection ensures that your team stay protected, and you stay compliant with UK safety regulations.

We focus on offering competitive prices without compromising on quality, so whether you're shoeing a single person or an entire team, XAMAX® is your best bet for safety footwear.

Our team is always on hand to guide you, and we offer bulk-buying options for cost-effective solutions without sacrificing safety.

Conclusion

Making the right choice between steel and composite toe cap safety boots can seem daunting, but understanding the requirements of your job and the benefits of each type will help you make the right decision.

While steel toe caps offer unbeatable strength, composite options provide lighter alternatives for those who are on their feet all day or work in environments where electrostatic discharge (ESD) protection is necessary.

XAMAX® supply safety footwear tailored to your specific needs. Our range of compliant foot protection ensures your workforce remains protected, comfortable, and safe on the job. Let us help you make the best choice for your safety footwear needs today.

If you are deciding between different types of safety boots or shoes, you might be choosing between composite and steel toe cap options. Here are the differences explained in one short post and some advice on which type is right for you, your budget and your job role. The Difference Between Composite And Steel Toe […]

Safety footwear is crucial for protecting workers from a variety of hazards at work. Whether you work in construction, healthcare, or food processing, wearing proper footwear can significantly reduce your risk of injury.

This article covers the various kinds of safety footwear, their materials, and uses across industries, along with a brief history of safety footwear.

- Page Contents

- A Brief History of Safety Footwear

- Safety Boots

- Safety Trainers

- Safety Shoes

- Safety Clogs

- Safety Wellies

- Why Choose XAMAX® for Your Safety Footwear?

- Conclusion

A Brief History of Safety Footwear

The development of safety footwear began in the early twentieth century, driven by industrial growth and a need to protect workers from potential hazards.

Before the introduction of safety boots, workers in sectors such as mining and construction were exposed to considerable risks from falling objects, sharp instruments, and hazardous chemicals. Steel-toe boots arrived in the 1930s, and they provided the first serious solution to toe protection.

Over time, safety footwear has advanced, incorporating details such as anti-slip soles, waterproofing, and electrical insulation to meet the demands of wide range of sectors.

Safety Boots

Safety boots are widely used in many sectors due to their durability and high level of protection. They often have steel or composite toe caps, midsole penetration resistance, and ankle support, making them ideal for physically demanding work.

Materials Used

- Leather: The most common material, known for its durability, water resistance, and ability to withstand harsh conditions.

- Rubber/Polyurethane: Often used in soles for its slip-resistant and oil-resistant properties.

- Composite Materials: Lightweight alternatives to steel, such as fibreglass and Kevlar, used for toe caps and midsoles.

Common Features

- 200-joule toe cap protection (steel or composite)

- Midsole penetration resistance (steel or composite plate)

- Slip-resistant soles (rated SRA, SRB, or SRC)

- Water resistance and fuel/oil resistance

- Heat or cold insulation, anti-static properties, and energy absorption at the heel

Uses in Different Industries

- Construction: Construction sites present a variety of risks, including falling objects, sharp debris, and uneven surfaces. Safety boots with steel toe caps and midsole puncture resistance (such as S3-rated boots) are essential in this line of work.

- Manufacturing: Safety boots provide protection against dangers of heavy machines and materials, including impacts and cuts. Heat-resistant soles are often used in fields such as as welding.

Safety Trainers

Safety trainers are a lightweight, flexible, and appealing alternative to safety boots. They are suitable for jobs that require agility or continuous standing, providing protection without limiting movement.

They rarely offer any ankle support, so are not a direct replacement for safety boots.

Materials Used

- Mesh/Nylon: Provides breathability, making trainers lighter and more comfortable for prolonged wear.

- Composite Toe Caps: Commonly used in trainers for lightweight protection.

- Rubber/TPU Soles: Offers slip resistance and flexibility.

Common Features

- Composite or steel toe caps

- Lightweight design for enhanced comfort

- Anti-slip soles, often with SRC ratings for maximum slip resistance

- Electrostatic discharge (ESD) protection for electronic environments

Uses in Different Industries

- Electronics: Safety trainers with electrostatic discharge (ESD) protection are ideal for environments where sensitive electronics are handled, preventing static buildup.

- Logistics: Lightweight trainers with anti-slip soles are perfect for workers in warehouses and distribution centers, where agility and comfort are critical for efficiency.

Safety Shoes

Safety shoes combine the formal appearance of conventional shoes with the protective qualities of safety boots, making them perfect for work areas that need both professionalism and safety.

Materials Used

- Leather and Synthetic Leather: Commonly used for durability and a smart appearance.

- Steel or Composite Toe Caps: Protect against impacts, while maintaining a sleek, low-profile look.

- Rubber Soles: Provide anti-slip properties and comfort.

Common Features

- Steel or composite toe caps

- Anti-slip soles

- Water resistance (in some cases)

- Smart, formal appearance

Uses in Different Industries

- Office Environments with Light Industrial Work: Safety shoes are perfect for managers or supervisors who need to move between office spaces and industrial work areas, providing them with the protection they need without compromising on style.

- Healthcare: Safety shoes are often used by healthcare professionals who need protection from sharp objects while maintaining a professional appearance.

- Hospitality: Slip-resistant safety shoes are vital in kitchens and food service environments where spills are common, providing both safety and style.

Safety Clogs

Safety clogs are slip-on shoes designed for simplicity of use in areas where hygiene and comfort are essential. They are particularly popular in industries that need frequent cleaning and hygienic environments.

Materials Used

- Polyurethane or PVC: Lightweight and waterproof, providing protection against spills and chemicals.

- Closed Toe Protection: Safety clogs may include steel or composite toe caps for impact resistance.

- Slip-Resistant Soles: Usually made of rubber or a slip-resistant synthetic material.

Common Features

- Slip-resistant soles (often SRA or SRB rated)

- Closed toes with steel or composite caps (depending on the model)

- Easy to clean and maintain

- Lightweight and comfortable

Uses in Different Industries

- Healthcare and Laboratories: Clogs are widely used in hospitals, dental practices, and laboratories due to their comfort, ease of cleaning, and ability to withstand spills and contaminants.

- Food Processing and Catering: In environments where hygiene is paramount, such as kitchens or food processing plants, clogs are preferred for their slip resistance and easy-to-clean surfaces.

Safety Wellies

Safety Wellington boots (wellies) are intended for use in areas where workers are exposed to water, mud, or hazardous substances. They offer complete waterproofing, toe protection, and specialised characteristics to tackle specific hazards.

Materials Used

- PVC or Neoprene: These materials provide complete waterproofing and resistance to chemicals, oils, and fuels.

- Steel or Composite Toe Caps: Offer protection from impacts.

- Rubber Soles: Ensure slip resistance on wet and slippery surfaces.

Common Features

- Full waterproof protection

- Steel or composite toe caps

- Slip-resistant soles, often with SRC ratings

- Cold insulation and penetration-resistant midsoles (for certain models)

Uses in Different Industries

- Agriculture and Landscaping: Safety wellies are ideal for farm workers, landscapers, and other outdoor workers, providing waterproof protection while working in muddy or wet environments.

- Construction: Workers who need to work in wet conditions, such as those working in foundations or with concrete, benefit from safety wellies with waterproof and anti-slip properties.

- Food Processing: In food processing plants, safety wellies protect against spills and ensure hygiene is maintained.

Why Choose XAMAX® for Your Safety Footwear?

XAMAX® is a BSIF Registered Safety Supplier, which ensures that all safety footwear we supply meets the highest levels of quality to meet compliance and the correct level of protection.

We supply a wide range of safety boots, trainers, shoes, clogs, and wellies for a variety of sectors, and suited to your specific needs.

When you choose XAMAX®, you're not only buying safety footwear, but also working with a supplier who is dedicated to supplying high quality products at low costs. Whether you work in construction, healthcare, or food processing, we have the right footwear for all of your workers.

Explore our full range of XAMAX® Safety Footwear today, or request a callback to speak with one of our team.

Conclusion

Choosing the right kind of safety footwear for your workplace is critical to worker safety, comfort, and productivity.

Whether you require the solid protection of safety boots, the flexibility of safety trainers, or the waterproofing of safety wellies, understanding the materials and features that are suitable for your work environment is essential to making the right choice.

Get In Touch - We're Here To Help

Safety footwear is crucial for protecting workers from a variety of hazards at work. Whether you work in construction, healthcare, or food processing, wearing proper footwear can significantly reduce your risk of injury. This article covers the various kinds of safety footwear, their materials, and uses across industries, along with a brief history of safety […]

Safety footwear is crucial for protecting workers from injuries at work, particularly in high-risk industries such as construction, engineering, and manufacturing. In the UK, strict safety standards exist to ensure footwear meets specific criteria for protection.

This article covers the key standards and safety ratings that determine whether footwear is safe to wear in the workplace and conforms with UK legislation.

- Page Contents

- The Importance of UK Safety Standards for Footwear

- Key UK Regulations for Safety Footwear

- Key Requirements of UK Safety Footwear Regulations

- Testing and Certification for Compliance

- XAMAX®: Your Trusted Partner for Safety Footwear

- Conclusion

The Importance of UK Safety Standards for Footwear

UK law is very clear when it comes to worker safety. The right footwear can prevent injuries that might otherwise result in lost time at work, long-term health problems, or even worse.

Safety boots are designed to protect workers from common hazards, such as heavy objects, sharp materials, and slippery floors. To ensure the right level of protection, the UK enforces certain safety standards for work boots and shoes.

Key UK Regulations for Safety Footwear

EN ISO 20345:2011

This is the main safety footwear standard in the UK, and it applies to all safety boots and shoes.

It says that footwear should protect the toes from impact (with a minimum 200-joule protection level), prevent foot punctures, and meet other specific requirements based on the workplace environment. This standard ensures that footwear provides a basic level of protection that is consistent across industries.

Personal Protective Equipment at Work Regulations 1992 (PPEWR 1992)

According to this regulation, employers must give their workers proper PPE, including safety footwear, without charge, when there are risks to health or safety in the workplace.

The footwear must be appropriate for the task at hand, properly fit the wearer, and provide enough protection for the hazards they face.

BSI (British Standards Institution) Compliance

The British Standards Institution (BSI) sets the bar for quality in the UK, and when it comes to safety footwear, BSI works with manufacturers to make sure the products meet required safety standards.

BSI compliance means that safety footwear has been independently tested and certified, giving employers peace of mind that the footwear meets safety regulations.

HSE Guidelines

The Health and Safety Executive (HSE) is the body responsible for enforcing workplace safety laws in the UK. HSE provides guidelines to help employers choose and provide the right safety footwear for their workers.

They also check that businesses are following the rules, conducting inspections, and investigating incidents. Failure to meet HSE standards can lead to fines or prosecution, so it’s essential to follow their advice.

Key Requirements of UK Safety Footwear Regulations

UK safety footwear regulations are strict about the level of protection safety boots must offer. The following are the key features required by law:

- Toe Protection (200-Joule Impact): Safety footwear that has toe protection must withstand the impact of 200 joules. That’s roughly the same as a heavy object, like a hammer or a brick, falling from height onto the foot. Any footwear with toe caps must meet this requirement.

- Slip Resistance: Footwear must also be slip-resistant to prevent accidents on surfaces like tiles, wet steel, or greasy floors. There are three ratings for slip resistance: SRA, SRB, and SRC, with SRC being the highest rating. Employers must select the right level of slip resistance depending on the workplace environment.

- Penetration Resistance: To prevent injuries from sharp objects, some safety boots have penetration-resistant midsoles. This feature is important on construction sites or anywhere with nails, scrap metal, or sharp tools on the floor.

- Water Resistance: In industries where workers are exposed to wet conditions, safety footwear must provide water resistance. This protects workers from discomfort and health problems caused by wet feet.

- Heat and Cold Insulation: Some work environments require extra protection from extreme temperatures. Footwear with heat or cold insulation (marked as "HI" for heat and "CI" for cold) helps keep workers comfortable and safe.

- Fuel and Oil Resistance: For workers in industries like automotive or chemical processing, the soles of their footwear need to resist fuel, oil, and other harmful chemicals. Boots marked with "FO" provide this type of resistance.

- Electrical Resistance: Workers exposed to electrical hazards need safety footwear that protects against electrical shock. Boots marked "I" (for insulation) or "ESD" (Electrostatic Discharge) are designed to prevent the buildup of static electricity or shield workers from electric shock.

You can learn more about the specific safety footwear ratings and codes associated with them in our Guide to Safety Footwear Ratings.

Testing and Certification for Compliance

Before any safety footwear can be sold in the UK, it must be rigorously tested to meet the requirements of EN ISO 20345:2011. Once a pair of boots has passed these tests, they are given a CE mark, proving that they meet all European safety standards.

In addition, buying from a BSiF Registered Safety Supplier ensures that the safety boots you purchase come from a trusted source, giving you the reassurance that they are compliant with UK regulations.

XAMAX®: Your Trusted Partner for Safety Footwear

When it comes to choosing safety footwear, compliance with UK safety standards is non-negotiable. As a BSiF Registered Safety Supplier, XAMAX® supplies only high-quality, certified footwear that meets EN ISO 20345:2011 standards.

Our range includes everything from steel-toe boots to waterproof wellingtons, ensuring protection across various industries. We work closely with our customers to provide footwear solutions that fit specific job requirements, always focusing on both safety and comfort.

We pride ourselves on being more than just a PPE supplier. We're a trusted partner that helps businesses protect their workers by offering a wide range of compliant safety footwear.

Conclusion

Understanding the UK safety standards for protective footwear is crucial for businesses and workers alike.

From preventing foot injuries to protecting against slips, sharp objects, and electric hazards, safety boots are a must in many workplaces.

By ensuring compliance with UK regulations and choosing the right protection levels, employers can create a safer work environment and reduce the risk of accidents.

XAMAX® provides reliable, compliant safety footwear to businesses across all industries. Choose us for your PPE needs, and rest assured that your team is equipped with the best.

Get In Touch - We're Here To Help

Safety footwear is crucial for protecting workers from injuries at work, particularly in high-risk industries such as construction, engineering, and manufacturing. In the UK, strict safety standards exist to ensure footwear meets specific criteria for protection. This article covers the key standards and safety ratings that determine whether footwear is safe to wear in the workplace and […]

Each year, thousands of work-related foot injuries could be avoided with adequate safety equipment. The appropriate protective footwear is essential for anybody working in construction, engineering, logistics, or food service.

In this article, we'll look at the most widespread workplace foot injuries, how protective clothing reduces these risks, and why complying to safety regulations is essential.

- Page Contents

- Common Workplace Foot Injuries

- How Safety Footwear Prevents Injuries

- Industry-Specific Footwear Requirements

- Compliance with PPE Regulations

- Why XAMAX®?

- Conclusion

Common Workplace Foot Injuries

Workplace foot injuries can range from minor bruising to more serious incidents that include broken bones, punctures, burns, and even amputations.

Crushing accidents, in particular, can result in the loss of toes or an entire foot, particularly in sectors such as construction and forestry, which use heavy machinery and tools such as chainsaws. Chainsaw accidents, for example, represent a considerable risk to forestry workers, highlighting the importance of chainsaw-resistant safety footwear.

Here are some examples of how these injuries can occur:

- Crushing injuries from falling objects or vehicles on construction and industrial sites.

- Puncture wounds from sharp objects like nails or glass penetrating the sole of the shoe.

- Burns from exposure to chemicals or extreme heat, often seen in manufacturing or foundry environments.

- Slips and falls from oil or water spills, a common risk in kitchens or warehouse floors.

In addition to severe injuries, chronic exposure to wet environments can induce debilitating foot conditions such as:

- Athlete’s foot: A fungal infection that thrives in damp, enclosed spaces, often exacerbated by wearing wet boots for long periods.

- Trench foot: A serious condition resulting from prolonged exposure to damp, cold environments, which can lead to tissue damage and even necrosis in extreme cases.

Both conditions can lead to long-term health problems and discomfort, underscoring the importance of wearing waterproof, breathable footwear that keeps feet dry and protected.

How Safety Footwear Prevents Injuries

Safety footwear is designed with features to counter the specific risks workers face. Depending on the industry, the type of footwear may include:

- Steel or composite toe caps: Prevent injuries caused by crushing or falling objects, offering toe protection up to 200 Joules, as mandated by EN ISO 20345.

- Puncture-resistant soles: Often steel or composite mid-soles, these prevent sharp objects from penetrating the foot from below.

- Slip-resistant outsoles: Rated SRA, SRB, or SRC, these are designed to reduce slips on various surfaces.

- Heat-resistant materials: Common in foundries and welding sites, where extreme temperatures can cause burns.

- Chainsaw-resistant materials: Especially in forestry, safety boots made with chainsaw-resistant fibers can prevent or reduce the severity of injuries.

- Waterproof materials: Designed to keep feet dry and prevent conditions like trench foot, these boots are essential for workers in wet or damp environments.

Industry-Specific Footwear Requirements

Each sector has unique challenges that define which sort of footwear is most suitable. Here's how safety footwear applies across various sectors:

Construction

Workers in construction encounter a variety of risks, including heavy falling objects, uneven terrain, and sharp debris.

Safety boots with steel toe caps, midsole protection, and slip-resistant soles are essential. Failure to wear appropriate footwear can result in serious injuries, including the amputation of toes or feet due to crushing incidents.

Manufacturing

Footwear in manufacturing may need to be resistant to punctures, chemicals, and heat.

For example, those working with heavy machinery or hot materials require heat-resistant boots with reinforced soles.

Forestry

Chainsaw-resistant footwear is essential for forestry workers who use chainsaws every day and move across tough terrain.

These boots are constructed with reinforced materials that prevent chainsaw penetration, significantly reducing the risk of life-altering injuries like amputations caused by chainsaw accidents.

Logistics and Warehousing

Slips, trips, and vehicle strike are the most common risks here. Workers need lightweight safety trainers with anti-slip bottoms and impact-resistant toe caps to stay on their feet when lifting and carrying goods.

Keeping feet dry in wet environments is crucial for preventing skin conditions.

Food Industry

Slip-resistant footwear is essential in kitchens and food processing facilities, where spills are commonplace. Cleanliness is also important, so washable and simple-to-clean materials are essential.

Workers in these industries are more likely to develop fungal diseases such as athlete's foot due to damp situations, so it is important to wear breathable, moisture-wicking footwear.

Compliance with PPE Regulations

Safety footwear in the UK is regulated by EN ISO 20345:2011 standards. This standard defines basic and additional protective criteria, such as impact, compression, and slip resistance.

Employers have to comply with the Personal Protective Equipment at Work Regulations 1992, which oblige them to provide appropriate PPE, including safety footwear, to their employees free of charge.

Non-compliance can have severe consequences, ranging from financial penalties to increased accident rates, harming both employee well-being and the company's bottom line.

Regular audits and risk assessments are necessary to ensure that all footwear in use meets current safety standards.

Why XAMAX®?

XAMAX® knows the unique safety requirements of various industries. As a BSIF-registered supplier, we supply high-quality, fully compliant safety footwear that not only meets but surpasses safety standards. XAMAX® offers an extensive range of solutions that meet your unique needs, including steel-toe boots for construction workers and slip-resistant shoes for hospitality staff.

Our health & safety products are designed to last, offering outstanding durability and comfort while being cost-effective. When you choose XAMAX®, you're not just buying personal protective equipment; you're investing in long-term safety and compliance.

Conclusion

Safety footwear plays a crucial part in minimising occupational foot injuries in all sectors.

Compliance with PPE regulations is essential for reducing crushing injuries in construction and ensuring slip resistance in a busy kitchen.

Employers have to ensure that all footwear fulfils the safety requirements of their particular sector, since this not only protects employees but also helps companies avoid the financial and legal ramifications of non-compliance.

Workers should always wear footwear that protects them against serious injury as well as conditions caused by extended exposure to wet environments.

Get In Touch - We're Here To Help

Each year, thousands of work-related foot injuries could be avoided with adequate safety equipment. The appropriate protective footwear is essential for anybody working in construction, engineering, logistics, or food service. In this article, we’ll look at the most widespread workplace foot injuries, how protective clothing reduces these risks, and why complying to safety regulations is […]

A PPE compliance audit for safety footwear is a must to ensure that all safety shoes, boots, trainers, and other protective footwear on site comply with the relevant regulations and meet workplace safety standards.

Because safety footwear is such a crucial part of personal protective equipment (PPE), carrying out regular audits helps uncover potential issues before they lead to accidents, protects workers, and ensures your company complies with UK health and safety regulations.

In this step-by-step (pun intended) guide, we'll walk you through (pun also intended) the basics of performing an audit for your workplace's safety footwear.

- Page Contents

- Step 1: Review Safety Footwear Regulations and Standards

- Step 2: Audit Safety Footwear Types and Applications

- Step 3: Inspect Safety Footwear Condition and Usage

- Step 4: Evaluate Supplier Certifications and Quality Assurance

- Step 5: Document Non-Compliance and Set Corrective Actions

- Why Choose XAMAX® for Your Safety Footwear?

- Conclusion

Step 1: Review Safety Footwear Regulations and Standards

Personal Protective Equipment at Work Regulations 1992

Employers are required to provide appropriate PPE, including safety footwear, at no cost to employees. The footwear must meet the standards outlined in EN ISO 20345:2011, which requires toe protection capable of withstanding 200 joules of impact.

BSI Compliance

The British Standards Institution (BSI) certifies safety footwear in the UK, ensuring compliance with BS EN ISO 20345:2011 for impact resistance, penetration resistance, and slip resistance.

HSE Guidelines

The Health and Safety Executive (HSE) outlines guidelines for PPE in the workplace. Employers must ensure that footwear provides the necessary protection against specific risks like electrical hazards, chemical exposure, slips and trips, or sharp objects.

Step 2: Audit Safety Footwear Types and Applications

During the audit, verify that the type of safety footwear provided matches the specific risks within your industry, workplace, and specific tasks. For example:

- Construction and Engineering: Workers should have boots with midsole penetration resistance, ankle support, and toe caps that protect against heavy objects and punctures.

- Food and Medical Sectors: Safety wellingtons or clogs with slip resistance, waterproofing, and easy-clean materials are essential.

- Manufacturing and Warehousing: Safety trainers with anti-slip soles, steel or composite toe caps, and electrical hazard protection should be considered.

Make sure each footwear type complies with EN ISO 20345:2011 and carries the necessary ratings such as S1, S2, S3 (which includes midsole protection) or SRC (slip resistance) depending on the work environment and job tasks.

Step 3: Inspect Safety Footwear Condition and Usage

A key part of this compliance audit is ensuring that footwear is in good condition and is being used appropriately. Inspect each pair for:

- Toe Cap Integrity: Ensure no visible dents or signs of failure in the toe cap.

- Sole Condition: Check for excessive wear in the sole, including cracks, tears, or loss of tread. Damaged soles compromise slip resistance and protection from sharp objects.

- Fit and Comfort: Confirm that employees have footwear that fits properly. Ill-fitting boots can cause discomfort and increase the likelihood of accidents due to tripping.

- Regular Replacement: Footwear should be replaced every 6 to 12 months depending on wear and tear, even if it still appears intact.

Step 4: Evaluate Supplier Certifications and Quality Assurance

For proper compliance and traceability, footwear should be supplied by a BSIF Registered Safety Supplier. Work with certified suppliers, such as XAMAX®, to make sure that every safety footwear meets EN standards and reliably has features like penetration resistance, anti-static qualities, and heat protection.

Choosing a trustworthy supplier ensures that those items have been carefully tested and approved for safety in the workplace.

Step 5: Document Non-Compliance and Set Corrective Actions

If any non-compliance issues are uncovered during the audit (such as missing ratings, damaged footwear, or inappropriate types), document these findings and create a corrective action plan. This might include:

- Replacing old or damaged footwear immediately.

- Providing additional training to staff on how to inspect and care for their footwear.

- Ensuring regular monitoring of the condition of safety footwear to catch issues early.

Compliance audits should be conducted at regular intervals (e.g., annually) or whenever significant changes to workplace conditions occur.

Why Choose XAMAX® for Your Safety Footwear?

XAMAX® is a trusted BSIF Registered Safety Supplier, which means all our safety footwear meets the highest industry standards and complies with EN ISO 20345:2011. Whether you need safety boots, trainers, or wellingtons, XAMAX® provides footwear that’s both durable and comfortable, tailored to your industry’s specific needs.

Choosing XAMAX® gives you peace of mind knowing that your workers are fully protected, while you remain compliant with UK safety regulations. Contact us for expert advice on how to keep your workforce safe.

Conclusion

Conducting a PPE Compliance Audit for Safety Footwear is a critical phase in ensuring your workforce's safety and protection while adhering to UK regulations.

Regular audits not only help to identify risks and potential noncompliance, but they also help establish a safety culture in the workplace.

Businesses could dramatically reduce their risk of workplace injuries by reviewing applicable legislation, checking the quality of safety footwear, and ensuring that proper footwear is worn for any given tasks.

Partnering with trustworthy suppliers like XAMAX®, who are fully compliant with BSI standards, ensures that your workers will be supplied with high-quality, certified safety footwear.

By remaining proactive and paying attention to PPE compliance, your organisation can avoid penalties, reduce workplace accidents, and promote a healthy, productive workplace.

Get In Touch - We're Here To Help

A PPE compliance audit for safety footwear is a must to ensure that all safety shoes, boots, trainers, and other protective footwear on site comply with the relevant regulations and meet workplace safety standards. Because safety footwear is such a crucial part of personal protective equipment (PPE), carrying out regular audits helps uncover potential issues before they […]

Safety footwear is essential for preventing workplace foot injuries and complying with UK regulations. Understanding the legal obligations, safety ratings, and industry-specific applications helps companies to provide the right level of safety to their employees.

This guide covers all you need to know about selecting, using, and maintaining safety footwear.

- Page Contents

- Introduction to Safety Footwear

- UK Safety Footwear Regulations

- Key Safety Footwear Ratings and Standards

- The Importance of Slip Resistance in Safety Footwear

- Industry-Specific Applications of Safety Footwear

- How to Select the Right Safety Footwear

- Proper Care and Maintenance of Safety Footwear

- Why Choose XAMAX® for Your Safety Footwear Needs

- Conclusion

Introduction to Safety Footwear

Safety footwear is a crucial part of Personal Protective Equipment (PPE) in a range of industries, including construction, manufacturing, logistics, and food services.

The correct footwear protects workers from multiple hazards such as sharp objects, falling materials, chemicals, electrical shocks, and so on.

Employers in the United Kingdom are legally obliged to provide safety footwear when a risk assessment identifies the need for it.

Wearing the correct safety footwear, whether to protect against foot injuries, slips, or dangerous substances, can help prevent serious accidents and ensure worker safety.

UK Safety Footwear Regulations

In the United Kingdom, the primary regulations governing safety footwear are the Personal Protective Equipment at Work Regulations 1992, as amended in 2011 and 2016, and the EN ISO 20345:2011 standard. These regulations provide the standard for ensuring that safety footwear provides suitable protection to workers.

Key Requirements Include:

- Toe Cap Protection (Where Applicable): Safety footwear with toe caps must offer protection against a 200-joule impact. This is a crucial requirement for footwear used in environments with risks of falling or heavy objects, ensuring the toes are adequately protected. Not all safety footwear has toe caps, but those that do must meet this standard.

- Slip Resistance: Footwear must meet minimum standards for slip resistance to prevent slips and falls in various work environments. This is tested under conditions outlined by SRA, SRB, and SRC standards, depending on the surface type (ceramic or steel) and lubrication (soapy water or glycerol).

- Markings and Labelling: Footwear must clearly display markings that indicate compliance with EN ISO 20345:2011, including the manufacturer's identification, size, and safety symbols that correspond to the specific protective features (e.g., SB, S1, S3).

- Fit for Purpose: Employers must ensure that all PPE, including safety footwear, is suitable for the tasks at hand. This means choosing footwear that meets the specific safety needs of the job role, such as resistance to heat, cold, chemicals, or punctures.

- Provision by Employer: The regulations state that employers are responsible for providing safety footwear at no cost to employees when the footwear is deemed necessary by a risk assessment.

- Ongoing Maintenance: Employers must also ensure that the footwear remains in good condition, conducting regular checks to identify wear and tear, and replacing any damaged or compromised footwear promptly.

These regulations are enforced by the Health and Safety Executive (HSE), and failure to comply with the standards can lead to penalties or legal consequences, especially in the case of workplace injuries.

The aim is to reduce foot injuries across sectors like construction, engineering, and manufacturing.

Key Safety Footwear Ratings and Standards

Safety footwear ratings and codes provide information about the level of protection they offer. These ratings ensure that the footwear is suitable for various hazardous environments.

Footwear Ratings:

- SB (Safety Basic): This is the base-level rating for safety footwear, requiring only basic toe protection. Footwear with this rating must have a protective toecap that can withstand up to 200 joules of impact. There are no additional requirements for features such as slip resistance or water penetration.

- S1: Footwear with an S1 rating includes all the requirements of SB, plus additional features. S1 footwear provides anti-static properties, heel energy absorption, and fuel oil resistance. This rating is suitable for environments where the primary hazards involve electrical discharges and oil spills.

- S1P: The S1P rating adds further protection to the S1 standard, offering penetration resistance in the midsole (typically with a steel or composite plate). This is essential for environments where sharp objects on the ground, like nails or shards, are a potential hazard.

- S2: Footwear with an S2 rating includes all the protection of S1 but adds water penetration resistance. S2 footwear is ideal for outdoor work environments where exposure to water or damp conditions is common.

- S3: S3 footwear includes all the features of S2 and adds midsole penetration resistance. It’s designed for harsh working environments, offering protection against sharp objects underfoot as well as water penetration.

- S4: Similar to S1 but intended for polymer/rubber boots, S4-rated footwear offers 200-joule toe protection, anti-static properties, and oil resistance, with the additional benefit of being fully waterproof and leakproof due to their molded design.

- S5: S5 footwear builds on the S4 rating by adding midsole penetration resistance. It’s used in high-risk environments that involve water, sharp objects, and slippery surfaces, commonly seen in industries such as construction and agriculture.

Slip Resistance Standards:

- SRA: Slip resistance tested on a ceramic tile floor with a sodium lauryl sulfate solution (similar to soap). It’s commonly required for environments like kitchens or medical facilities where slipping hazards on wet tiles are frequent.

- SRB: Slip resistance tested on a steel floor with glycerol (similar to oil). This is used in environments where oils or lubricants are present, such as workshops or garages.

- SRC: This combines both SRA and SRB testing methods, making SRC-rated footwear highly versatile and the best choice for environments with varied surfaces and slip risks.

ASIDE: There were some amendments to the standards in 2022 not included in this article yet. See the changes here.

The Importance of Slip Resistance in Safety Footwear

Falling, tripping, and slipping are some of the most frequent accidents at work. Slips, trips, and falls accounted for 32% of non-fatal workplace injuries in the UK in 2022/23, making slip-resistant footwear an essential safety measure.

According to the HSE, minimising incidents like these can significantly reduce injury rates and lost workdays.

Industry-Specific Applications of Safety Footwear

Each industry has unique risks and safety requirements, so the type of safety footwear required differs significantly. The following are examples of safety footwear uses in several sectors:

Construction and Engineering

- Primary Hazards: Falling debris, sharp objects, and uneven ground.

- Recommended Footwear: S3-rated boots with midsole penetration resistance and ankle support are essential for protecting against foot injuries. Waterproof and anti-slip features are also recommended for outdoor conditions. Slip-resistant ratings of SRC are often necessary.

Manufacturing and Warehousing

- Primary Hazards: Heavy machinery, slippery floors, and moving objects.

- Recommended Footwear: S1P footwear is generally suitable, providing anti-static properties, penetration resistance, and oil resistance. Slip-resistant footwear is vital in manufacturing plants and warehouses, where spills are common.

Chemical and Oil Industries

- Primary Hazards: Chemical spills, flammable liquids, and oily surfaces.

- Recommended Footwear: S4 or S5 boots offer full waterproof protection and resistance to chemicals, with slip resistance and penetration protection to prevent accidents in hazardous environments.

Agriculture and Food Processing

- Primary Hazards: Wet, muddy conditions, and exposure to chemicals.

- Recommended Footwear: S4 or S5-rated safety wellingtons, which offer full waterproof protection, slip resistance, and fuel/oil resistance. White wellingtons are commonly used in food processing environments for easy visibility of contamination.

How to Select the Right Safety Footwear

Choosing the correct safety footwear for your needs requires assessing workplace hazards and matching appropriate footwear ratings to those risks.

Here's what you should consider:

- Assess the risks: Conduct a risk assessment and identify possible risks such as falling items, slippery flooring, or chemical exposure.

- Check the ratings: Match the identified hazards to the appropriate ratings to ensure your footwear meets EN ISO 20345:2011 requirements.

- Consider Comfort: Safety footwear should be both protective and comfortable to wear for extended periods of time. Lightweight composite-toed boots can help ease foot fatigue.

- Industry Requirements: Some sectors, such as electronics, may require specialised footwear, such as ESD-rated boots, to avoid static discharge.

- Durability and Maintenance: To ensure durability, choose sturdy footwear that can survive difficult working conditions and maintain it on a regular basis.

Proper Care and Maintenance of Safety Footwear

To extend the life of safety footwear and assure continuous protection, proper care and maintenance is necessary. The need for this would be highlighted during a PPE audit specifically for safety footwear.

Here are a few tips:

- Regular Cleaning: Clean your boots on regularly to remove dirt, chemicals, or oils that could damage the material.

- Drying: If your footwear becomes wet, dry it naturally rather than using direct heat sources, which can deform or harm the material.

- Regular inspection: Look for indications of wear and tear, such as cracks, worn soles, or damaged toe caps.

- Storage: Keep boots in a cool, dry area away from chemicals and excessive heat.

By following these maintenance procedures, you can extend the life of your safety footwear and remain compliant with safety standards.

Why Choose XAMAX® for Your Safety Footwear Needs

XAMAX® is more than just a safety supplier – we’re a trusted partner for businesses across the UK. As a BSIF-registered supplier, we guarantee that all our safety footwear complies with EN ISO 20345:2011 standards.

Our extensive range covers every industry, from heavy-duty construction boots to lightweight safety trainers for electronics work. We also offer waterproof wellingtons for industries like food processing and agriculture.

Here’s why businesses trust XAMAX®:

- BSIF Registration: XAMAX® is a British Safety Industry Federation (BSIF) registered supplier, ensuring that all the PPE we provide meets the highest safety standards.

- Expert Advice: Our team is available to guide you through the process of selecting the best safety footwear for your specific needs.

- Competitive Pricing: XAMAX® offers competitive pricing without compromising on quality, ensuring you get the best value for money.

If you're looking to kit out your team with high-quality, compliant safety footwear, look no further than XAMAX®.

Conclusion

Choosing the appropriate safety footwear is crucial to maintaining a safe and productive work environment. The rules, ratings, and standards addressed in this guide lay the foundation for choosing footwear that meets the right safety requirements while protecting workers from different hazards they might face.

From construction and manufacturing to food processing and healthcare, selecting the appropriate footwear is not just about compliance; it’s about reducing injuries, increasing comfort, and enhancing productivity.

By understanding and adhering to key safety standards like EN ISO 20345:2011 and ensuring that your footwear meets the specific needs of your industry, you can help safeguard your workforce against accidents and injuries.

Whether it's for protection against slips, chemical exposure, or heavy impact, providing your staff with the proper safety footwear is a proactive step towards workplace safety.

At XAMAX®, we understand how crucial this is. As a BSiF-registered safety supplier, we offer a range of safety boots and shoes that comply with all necessary standards and regulations.

With our expertise, you can be confident that your team is protected with high-quality, compliant PPE footwear, and our team is ready to help you select the best footwear for your specific needs.

Get In Touch - We're Here To Help

Safety footwear is essential for preventing workplace foot injuries and complying with UK regulations. Understanding the legal obligations, safety ratings, and industry-specific applications helps companies to provide the right level of safety to their employees. This guide covers all you need to know about selecting, using, and maintaining safety footwear. Introduction to Safety Footwear Safety footwear […]

Style and colour may be your first thoughts when choosing new safety boots or shoes, but you should be more concerned about the Safety ratings of your chosen footwear. The fit, suitability for your job and the protection standards (aka: Safety Boot Ratings) should be at the forefront of your mind.

This is a guide to the safety standards, classifications, ratings and codes for work boots, protective shoes or in fact any workplace safety footwear. It will help you make the right choices to ensure you the correct level of protection for your feet. Whatever job you do or are buying footwear for, this guide covers it.

- Page Contents

- What You Need To Know

- Standard EN ISO 20345:2011

- Safety Rating Abbreviations & Codes

- Anti-Slip Footwear Ratings

- What Safety Footwear is Right For You?

- Comfort Levels

- Correct Level of Foot Protection

- Buying Second Hand

- Looking After Your Safety Footwear

Safety Footwear Regulations ARE PPE Regulations

All forms of PPE are covered and described by the Personal Protective Equipment (PPE) at Work Regulations 1992. An update was made in 2002, and another update happened in 2011.

It is an employer's responsibility to keep employees safe, including providing PPE and any other safety equipment workers may need. This absolutely includes safety footwear.

Safety Boot Ratings Are The Same for All Footwear

The safety footwear standards in the UK are the same as the footwear standards across Europe: EN ISO 20345:2011.

Safety Shoe ratings are the same as Safety boot ratings are the same as Safety Trainer ratings etc.

Under this standard, all safety footwear must protect the toes against a 200 joule impact. Be that work boots, wellingtons, safety shoes or safety trainers. It is understandable to think safety shoes may come under a different set of rules as foundry steelies - but you would be mistaken.

All safety footwear falls under the same regulations. A pair of safety trainers is comparable to a pair of safety Wellington Boots. A pair of nurse's non-slip clogs has the same legal regulations as the boots you would wear in construction. That regulation is called: EN ISO 2034:2011

So whatever footwear you need to use for your work tasks to keep your feet safe from injury or disease, you would follow the same guidelines and codes as for any safety boot.

Makes everything so much simpler when you only need to digest 1 set of guidelines.

What Does The Safety Footwear Standard EN ISO 20345:2011 Mean?

EN ISO 20345:2011 is not as complicated to understand as it first appears. It simply specifies the basic/additional safety footwear requirements to meet the standard.

Let's break it down...

- EN - This is the current applicable standard across Europe

- ISO - All footwear PPE products must meet the minimum safety standards as defined by the International Organization for Standardization.

- 20345 - This is the assigned legislation number.

- 2011 - This is the year the safety standard around footwear was updated. It now requires that safety footwear must now protect against a 200 Joule impact at the toes before failing.

ASIDE: There were some amendments to the standards in 2022 not included in this article yet. See the changes here.

Safety Footwear Abbreviations & Codes You Should Look Out For

There is an array of foot protection in the form of boots or shoes available apart from the standard toe-cap. For instance, some safety footwears are anti-static and some are ECD (Electro-Static Discharge) resistant. Some offer protection for the metatarsal, some have steel plates in the sole to prevent penetration and some prevent cuts (have you ever seen a chainsaw-proof boot?).

As is usual in PPE and Health & Safety, codes and abbreviations are used to describe these features. See the table below for a non-exhaustive list that is sure to grow with time.

| Code | Icon | Meaning |

| A | Anti-static | |

| AN | Ankle Protection | |

| C | Conductive | |

| CI | Cold Insulation | |

| CR | Cut Resistant Upper | |

| E | Energy Absorption | |

| FO | Fuel/Oil Resistant Outsole | |

| HI | Heat Insulation | |

| HRO | Outsole is Resistant to Hot Contact | |

| I | Electricity Insulated | |

| M | Metatarsal Protection | |

| P | Penetration Resistance | |

| WR | Water Resistance | |

| WRU | Water Penetration and Water Absorption Resistant Upper | |

| ESD | Electro-Static Discharge Resistant |

What are the Safety Footwear Ratings?

The above codes are very specific, but the level of protection footwear gives has a clear system of ratings combining many of the above codes. These are known as "S ratings". You are probably already familiar with some of them: S1, S2, S3 (and now S5).

This table lays out the 6 safety boot/shoe ratings - an explanation of each is below. Click on the rating to jump directly to it's full explanation.

| Rating | Icon | Meaning |

| SB | Safety Basic (Has Toe Protection) | |

| SBP | As SB with additional Mid-Sole protection against penetration | |

| S1 | Anti-Static, Oil-Resitant and Energy Absorption | |

| S1P | As S1 with additional Mid-Sole protection against penetration | |

| S2 | Prevents Water Penetration | |

| S3 | Midsole Penetration Resistance | |

| S4 | Leak-Proof | |

| S5 | Leak-Proof with Midsole Penetration Resistance |

What do the Safety Footwear ratings mean?

Please Note: After SB, the standards feature all the SB basics, but have extra protection or features.

- SB - Safety Basic - This is the basic standard for safety footwear and must have toe protection that can withstand a 200 Joule impact. There can be (and most likely will be) other standards alongside the SB which will appear as other symbols as mentioned above. EG: SB-FO would have the basic standard of safety toe-cap, but also features a Fuel/Oil Resistant Outsole.

- SBP - This is the same as the basic standard for safety footwear but includes a mid-sole plate (steel, or composite material) to protect the foot against penetration.

- S1 - S1 footwear is anti-static, resistant to fuel oil and features energy absorption at the heel. As with SB, other symbols can be added, EG: S1-HI would be an S1 shoe or boot, but is also insulated against heat.

- S1P - S1P footwear the same as S1 footwear but including a steel or composite plate in the Mid-Sole to protect against penetration from under foot.

- S2 - S2 footwear has all the aspects of S1 footwear, but adds prevention of water absorption for the upper. Again, codes can be added as they are with S1 and SB.

- S3 - You will find the same safety elements as contained in S2, plus a penetration resistant midsole. Again, codes can be added as they are with S2, S1 and SB. Find S3 rated safety footwear here.

- S4 - An S4 boot encompasses the same level of protection as an S1, however it is moulded from a polymer or rubber that makes them completely waterproof and leak-proof. A safety welly would be S4 at the least, and other codes can be added when the boot achieves other safety standards.

- S5 - S5 gives you all the safety footwear features of the S4, plus midsole penetration resistance. Here is an example of S5 safety boots.

The Non-Slip/Anti-slip Footwear Standards

Slips account for a huge percentage of workplace accidents, so it is absolutely vital that there are separate safety standards. Workers and employers need to be able to rate the slip-resistance of safety footwear.

Slipping is measured using 2 different lubrication mediums on 2 different surfaces, or both, using a "Pendulum Slip Test" system - a type of "Tribometer". That's a tool that measures the tribological quantities of the interacting surfaces in relative motion. Friction... it measures friction.

Here are the 3 standards

| Rating | Icon | Test Medium |

| SRA | Slip resistance is tested on ceramic tile which has been saturated with Sodium Lauryl Sulphate (the active ingredient in soap) | |

| SRB | Slip resistance is tested on Steel plate which has been saturated with Glycerol | |

| SRC | Slip resistance is tested and passed against the same conditions as SRA and SRB |

What Is the Best Safety Footwear for Me?

Knowing the safety standards and the conditions you will be working in is the first step to buying the correct safety boots, shoes or trainers for you.

You could stop reading here and still make an informed choice. However, there are other practicalities you should probably think about.

Here are some extra tips before you buy...

Comfortable Footwear is Key to Productivity

Have you ever trudged through mud in the garden, walking the hills or at a festival? The added weight on your feet makes every step more difficult and the consequence is pure misery.

That is not conducive to a good day at work!

More and more lightweight safety footwear is becoming available. No longer are the ugly old Miners external steel toe-caps the only solution to foot protection. Infact, those aren't even legal anymore and you should not be able to find them anywhere but a museum.

Modern technology has leapt forward allowing such trends as safety trainers, high protection wellington style boots, cut-resistance and all manner of other specialist foot protection - without compromising on comfort, flexibility and *ahem* style.

Ensure You Get The Correct Level of Foot Protection

Now you know what all the safety footwear ratings, standards and codes mean, you have no excuse for getting the wrong level of protection for your working environment.

Toe-protection is the minimum requirement for footwear to be classed as "safety", but there is a good chance you may require more.

Consider the work you do and the environment you do it in. Construction workers will definitely need the minimum of a toe-cap, but you would be wise to consider mid-sole protection too. You'd be glad of that if someone leaves a nail protruding from a 2 by 4. You should consider ankle support for uneven ground (that is why Rigger Boots are not really suited for building sites).

If you work with fuels or inflammables/flammables, you should use an anti-static and Fuel/Oil resistant footwear.

Working with electricity? You should consider electrical-resistant footwear.

Working with heat hazards like foundry working or welding? You would need a HRO boot.

Work with Food, in a Medical Lab or Clean Room? You will probably need a safety shoe that is Slip-Resistant, Washable and White.

Are you or your employees Vegan? Serious question. There are Vegan safety trainers, and you might need to consider this if any of your employees are vegans.

The list goes on, but you get the jist.

Get the Correct Size and Fit

it is essential footwear fits your feet properly as you will spend your entire working day in these boots or shoes.

Everybody is different, so it might be that in order to get the right level of protection that fits you properly, you might need to forgo those all singing, all dancing über-boots that impress your mates. Get something more conservative looking, yet correct and safe.

Don't be afraid to invest in some good quality insoles or socks designed to improve your comfort either.

Absolutely NEVER buy second hand safety footwear

Do we really need to explain this?

The only way you can be certain of the history of a piece of safety equipment is buying it new. Buying second hand safety footwear opens you up to so much risk that it is simply not worth it.

You need your toe protection to withstand the 200 Joules it is designed to withstand. If you do not know the history of the footwear, you will not know if that 200 Joules has already been exceeded and the protection rendered useless. Nobody wants to find out there is a broken toe-cap whilst a forklift runs over their foot.

And the price ranges of footwear with differing safety specs really means you have no excuse not to buy new.

Look After Your Footwear and Your Footwear Will Look After You

It is the same with all your PPE to be honest - your foot protection can only take so much abuse before it fails. So the best thing to do is protect your footwear like it protects you. Boots or Shoes will last much longer too, saving you money in the long-run.

- If they get muddy, clean them.

- If they are wet, dry them naturally.

- Use laces properly (don't slip them on and off and stretch them).

- Store them carefully, don't let them rattle around in the back of the van.

- Invest in some Dubbin for leather boots or shoes

And most importantly, if you have an incident where the protection level may have been compromised, CHECK your footwear thoroughly for any failures. If in doubt, replace them immediately.

You need your feet.

Get In Touch - We're Here To Help

Style and colour may be your first thoughts when choosing new safety boots or shoes, but you should be more concerned about the Safety ratings of your chosen footwear. The fit, suitability for your job and the protection standards (aka: Safety Boot Ratings) should be at the forefront of your mind. This is a guide […]

Safety boots are a necessity for ensuring your feet are as protected as possible while you carry out your work duties. There are a number of options on the market but it is important you buy work safety boots that are comfortable and suit the roles you carry out.

Perhaps steel toe capped boots are the right choice, maybe composite toe caps are better suited. The only way to know what you need from your safety boots is to consider the hazards and risks associated with your job, and compare that to the ratings and codes each boot offers.

There are all manner of safety footwear ratings, codes and specifications nowadays - all created for specific job roles and applications. Get it wrong, and not only do you risk falling foul of the law, but you risk injury to yourself.

So how do you choose the right pair of boots for you?

- Page Contents

- Trusting a Brand

- Buying Second-Hand

- Comfort

- Correct Fit

- Protection Levels - 5 examples

- Risk Assessment

- Legislation

Opt for a trusted brand - it will be cheaper in the long run

You can find cheap work boots down the centre aisle of many low cost supermarkets. They are perfectly fine for knocking around the garden or allotment, and would likely stand the test of time for domestic use.

But would they last in your workplace, doing your job, for your hours, on your feet?

There is a reason they are cheap.

What do supermarkets know about your workplace safety? It is unlikely the footwear has been through the same vigorous testing done by specialist safety footwear brands such as Rock Fall, or PPE experts like Portwest. This testing is absolutely necessary to ensure each boot specification meets the safety standards and protection we as workers require and expect.

The British Safety Industry Federation have strict standards for membership of companies, Xamax, Rock Fall and Portwest are all members of the BSiF.

Make sure your boots are made and sold by a member of the BSiF and stick with a name you can trust.

You will find that branded, safety specific boots for most applications cost much less than you would think, plus they will last longer.

Never Buy Second-Hand

There is no disputing this one and it should go without saying: NEVER buy second-hand safety boots.

You do not know what foot injury disasters they have already protected against and no doubt they will come with added wear and tear. What if they have already exceeded their safe limit? Nobody wants to find out their boots are broken as a Caterpillar drives over their foot.

Soles wear based on the wearer's gait, so by wearing somebody else's tread, you will be affecting your own footsteps and balance. This could potentially lead to slow damage to almost any joint in your body. Back, hips knees, ankles and feet all require correct alignment to remain healthy.

Don't do it to yourself.

Go for Comfortable Features

When deciding on what style of boot perfectly suits your working environment, you should be careful not to compromise on your own comfort. Lightweight work boots with a composite toecap are often opted for rather than the traditional steel toe cap boots purely for comfort reasons.

If a metal-free safety boot is available with the correct safety rating for your job description, it tends to be much lighter to carry on your feet, helping to avoid fatigue throughout the day.

If you absolutely must have steel toe-capped boots in order to remain safe at work, then you should not opt for buying a big riggers boot when a pair of ankle boots would suffice