Worker safety is essential in industries where there are hazardous airborne particles, chemicals, or gases. Respiratory Protective Equipment (RPE) is crucial for protecting workers from respiratory diseases and long-term health issues. In the United Kingdom, various rules provide clear principles that ensure that workers are adequately protected.

This guide gives a full review of the UK respiratory protection safety requirements, with an emphasis on the legal framework and how to choose the appropriate RPE for your staff.

- Page Contents

- The Legal Framework

- Respiratory Protective Equipment (RPE) Standards

- Choosing the Right Respiratory Protection

- XAMAX®: Your Partner in Respiratory Protection

- Conclusion

The Legal Framework

The legal framework for respiratory protection in the UK is built on a set of regulations intended to ensure worker safety and correct usage of Personal Protective Equipment (PPE).

These regulations require that both companies and employees follow specific guidelines for selecting, using, and maintaining RPE.

Control of Substances Hazardous to Health (CoSHH) Regulations 2002

CoSHH is one of the most important regulations for workplace health and safety. It applies to all organisations where hazardous substances are used. These include protection against chemicals, dust, and fumes, which can harm workers' health if inhaled.

Under CoSHH, employers must do the following:

- Identify what hazardous substances are present in the workplace.

- Assess the risks associated with these substances.

- Control exposure by using the right protective measures, including providing RPE (respiratory protective equipment) to employees.

- Ensure workers are trained to use the equipment properly.

Personal Protective Equipment (PPE) at Work Regulations 1992

The PPE at Work Regulations 1992 require employers to provide suitable protective equipment whenever there are risks to workers' health and safety. For respiratory protection, this means providing the correct RPE based on the hazards identified in the workplace.

Employers must ensure that:

- The RPE provided is appropriate for the type of work and level of risk.

- The equipment is well-maintained and clean.

- Workers are trained to use and care for their RPE properly.

The Management of Health and Safety at Work Regulations 1999

This regulation requires employers to carry out risk assessments for health and safety hazards. It ensures that protective measures are in place and that workers are given the right equipment, training, and supervision.

For respiratory protection, this means:

- Employers must regularly review and update their risk assessments to make sure the right RPE is in use.

- They must train workers on the correct use of RPE and keep an eye on the equipment's condition.

Respiratory Protective Equipment (RPE) Standards

RPE must meet specific UK and European standards. The most common standard is EN 149 for disposable filtering facepieces, which provides three levels of protection: FFP1, FFP2, and FFP3.

- FFP1 masks provide the least protection and are suitable for low levels of dust.

- FFP2 masks offer moderate protection against dust, mists, and fumes.

- FFP3 masks give the highest protection and are often used in more dangerous environments with high levels of harmful dust and particles.

There are also half-face and full-face respirators that must meet EN 140 and EN 136 standards. These provide higher levels of protection and can be fitted with different types of filters based on the substances in the air.

Choosing the Right Respiratory Protection

Choosing the right RPE depends on the risks in the workplace. Employers need to consider factors like the type of substance, how much of it is in the air, and how long the worker will be exposed to it. It's important to choose equipment that fits well and is comfortable for the wearer to ensure they use it correctly.

Workers must also be trained in how to wear and care for their RPE to keep it working properly. For example, a dust mask that doesn’t fit properly won’t give full protection, so fit-testing is essential.

XAMAX®: Your Partner in Respiratory Protection

XAMAX® recognise the importance of providing suitable respiratory protection for your employees. As a BSIF Registered Safety Supplier, we ensure that all of our RPE meets UK safety standards, giving you confidence that your workforce is safe.

We supply a wide range of RPE, from disposable masks to full-face respirators, ensuring that we have a solution for most sectors and risk levels. Our friendly staff can assist you in choosing the right equipment for your requirements, and this blog provides guidance on maintenance and care to make sure your RPE remains in perfect working order.

When you use XAMAX®, you're buying more than just high-quality safety equipment; you also get professional assistance to keep your workers safe.

Conclusion

Knowing and complying to the UK safety regulations for respiratory protection is vital for protecting your employees from dangerous dust, fumes, and gases.

Employers need to conduct regular risk assessments, supply suitable RPE, and ensure employees receive training in its use.

Whether you’re working with low levels of dust or dangerous chemicals, the correct respiratory protection is key to preventing serious health issues.

If you need help choosing the right RPE, XAMAX® is here to support you with our wide range of high-quality products and expert advice.

Worker safety is essential in industries where there are hazardous airborne particles, chemicals, or gases. Respiratory Protective Equipment (RPE) is crucial for protecting workers from respiratory diseases and long-term health issues. In the United Kingdom, various rules provide clear principles that ensure that workers are adequately protected. This guide gives a full review of the […]

A key element of workplace safety is respiratory protection, especially in sectors where employees are exposed to hazardous airborne particles. Wearing the right respiratory protection equipment (RPE) is essential to preventing major respiratory illnesses associated with everything from dust in construction to hazardous substances in manufacturing.

The most significant regulations, classifications, and applications of respiratory protection in many sectors are covered in this guide, giving workers and managers the knowledge they need to ensure a safe work environment.

- Page Contents

- Introduction to Respiratory Protection

- Key UK Regulations for Respiratory Protection

- Types of Respiratory Protection

- Respiratory Protection Ratings Explained

- Applications by Industry

- XAMAX®: Why Choose Us?

- Conclusion

Introduction to Respiratory Protection

Respiratory Protective Equipment (RPE) is essential in workplaces where employees are exposed to airborne hazards such dust, fumes, vapours, and gases.

Proper RPE use can help to prevent long-term health issues such as chronic respiratory diseases, lung cancer, and other major disorders.

Workers and employers can ensure effective protection in any hazardous environment by understanding the relevant legislation and protective ratings.

Key UK Regulations for Respiratory Protection

Several regulations govern the use of respiratory protection in the UK. Employers must comply with these rules to ensure the safety of their workers.

Control of Substances Hazardous to Health (COSHH) Regulations

The COSHH Regulations 2002 are one of the most important frameworks that require employers to control exposure to hazardous substances in the workplace. According to COSHH, employers must:

- Assess the risks: Identify the hazardous substances and evaluate the level of exposure.

- Provide adequate RPE: Ensure that the provided respiratory protection is suitable for the work environment.

- Conduct face fit testing: Tight-fitting respirators must be tested for a proper seal on each employee's face.

- Monitor health: Regular health surveillance is required for workers who may develop lung diseases.

Personal Protective Equipment at Work Regulations 1992

The PPE at Work Regulations 1992 mandate that employers must provide suitable personal protective equipment, including RPE, at no cost to the employee. These regulations also require employers to:

- Ensure that PPE is appropriate for the risks involved.

- Maintain and replace the equipment regularly.

- Train employees on the correct usage and limitations of RPE.

British Standards Institution (BSI) Compliance

BSI is responsible for setting standards for the design and testing of PPE. Respiratory protection must comply with BS EN 149, the UK standard for filtering facepieces (FFP), and other relevant standards.

Employers should ensure that all RPE is certified by BSI for protection against specific hazards.

Fit2Fit Accreditation for Face Fit Testing

The Fit2Fit accreditation ensures that those performing face fit tests for tight-fitting respirators are competent. Testing ensures the mask properly seals to the wearer’s face, reducing the risk of inhaling contaminants.

Types of Respiratory Protection

There are several types of RPE, each suited for different hazards and industries. Choosing the right one depends on the level of airborne hazard and the type of work performed.

Disposable Dust Masks

These masks, also known as filtering facepieces (FFP), provide protection against dust and non-toxic particles. They are common in construction and light industrial work where low-level dust exposure occurs.

Materials: Typically made from lightweight fabric with integrated particulate filters.

Half-Face Respirators

Half-face respirators cover the nose and mouth, offering protection against dust, fumes, vapours, and some gases. These are suitable for industries dealing with more hazardous airborne particles, such as metalworking or chemical processing.

Materials: Made from silicone or rubber for durability, with replaceable filters.

Full-Face Respirators

Full-face respirators provide a higher level of protection, covering the entire face to protect both the respiratory system and the eyes from exposure to harmful substances. Commonly used in hazardous environments such as chemical plants.

Materials: Made from durable rubber or silicone with replaceable filters.

Powered Air-Purifying Respirators (PAPR)

PAPRs use a battery-powered fan to draw air through filters. These are often used in environments where workers are exposed to toxic fumes, dust, or vapours for extended periods.

Materials: Lightweight and designed for long-term use with advanced filtration systems.

Self-Contained Breathing Apparatus (SCBA)

SCBAs provide breathable air from a tank and are used in environments with little or no oxygen, such as confined spaces or emergency response situations.

Materials: High-strength materials to withstand extreme conditions.

Respiratory Protection Ratings Explained

The level of protection provided by respiratory equipment is measured using specific ratings and assigned protection factors (APF).

FFP1, FFP2, and FFP3 Ratings

These ratings apply to filtering facepieces and represent the level of protection they offer against particulate hazards:

- FFP1: Filters at least 80% of airborne particles. Suitable for light dust environments, such as basic construction tasks.

- FFP2: Filters at least 94% of airborne particles. Suitable for environments with moderate hazards, such as sanding and plastering.

- FFP3: Filters at least 99% of airborne particles. Recommended for high-hazard environments, such as working with asbestos or toxic chemical fumes.

APF (Assigned Protection Factor)

The Assigned Protection Factor (APF) is an important measure for determining the amount of protection provided by respiratory protective equipment (RPE). APF ratings indicate how well the respirator reduces exposure to hazardous substances when worn correctly. The higher the APF, the more effective the protection.

For example, an APF of 10 means that the respirator reduces the user’s exposure to airborne contaminants to 1/10th of the concentration in the surrounding air. An APF of 20 reduces it to 1/20th, and so on. Knowing the APF of a respirator allows employers and workers to make informed decisions about whether the equipment is suitable for the level of hazards present in the workplace.

In the UK, the Health and Safety Executive (HSE) provides guidelines on selecting respirators with appropriate APF levels for different hazardous environments. Different types of RPE, such as filtering facepieces, half masks, and full-face masks, all have varying APF values. It's essential to refer to these ratings when assessing the suitability of respiratory protection for specific tasks.

Applications by Industry

Different industries require different types of respiratory protection depending on the specific hazards present. Here’s a breakdown of common industries and the type of respiratory protection needed:

Construction

Construction workers are often exposed to dust, fumes, and other airborne particles from materials like concrete, brick, and asbestos. FFP3 masks are typically required to protect against these hazards.

Regular fit testing and maintenance are critical to ensure continued protection.

Manufacturing

In industries like metalworking, painting, and chemical processing, workers may be exposed to hazardous fumes and vapours.

Half-face and full-face respirators with appropriate filters are essential to protect workers from harmful gases and chemicals.

Agriculture

Farmers and agricultural workers face risks from dust, pesticides, and animal dander. Disposable FFP2 or FFP3 masks are often used to protect against these particulates, while half-face respirators are useful for chemical applications.

Automotive and Engineering

Workers in automotive repair and engineering are often exposed to dust, solvents, and other chemicals.

Half-face respirators with P2 or P3 filters offer effective protection from inhaling dangerous fumes and particles during tasks such as sanding, welding, and painting.

Mining and Quarrying

Workers in the mining industry are exposed to high levels of dust and sometimes toxic gases. Full-face respirators and PAPRs are commonly used to provide sufficient protection in these hazardous environments.

Woodworking

In woodworking, wood dust is the primary hazard. FFP2 or FFP3 dust masks provide essential protection for workers cutting, sanding, or shaping wood, as these tasks generate fine particulate matter that can be harmful to the lungs.

XAMAX®: Why Choose Us?

When it comes to respiratory protection, you can trust XAMAX® to supply the highest quality PPE that meets UK safety standards.

As a BSIF registered safety supplier, we ensure that every product complies with regulations and is designed to provide maximum protection for your workforce.

Whether you're in construction, manufacturing, or any other industry, XAMAX® offers a wide range of respiratory protection to suit your specific needs.

Protect your team with our industry-leading respiratory protective equipment. Explore our full range of RPE or request a callback for expert guidance on choosing the right RPE for your business.

Conclusion

Respiratory protection is a crucial part of workplace safety, especially in sectors where workers are exposed to air-borne contaminants like dust, fumes, vapours, or gases. Understanding the many forms of RPE, regulatory demands, and appropriate protection ratings enables companies and employees to make educated decisions about their safety.

Employers must comply with requirements set by UK legislation such as COSHH and PPE at Work in order provide proper protection to their employees. Companies can significantly reduce the risk of respiratory infections among their employees by selecting the appropriate respirator, conducting face fit tests, and ensuring regular maintenance.

Whether you need basic dust masks for light construction or advanced PAPRs for chemical plants, selecting the correct RPE is crucial for worker health and safety. Always ensure that your equipment complies with the highest safety standards and is suited for your industry’s specific needs.

XAMAX® are committed to providing BSIF-certified respiratory protection products that meet UK safety standards. Our range includes everything from disposable masks to full-face respirators, ensuring that you have the right protection for any job.

A key element of workplace safety is respiratory protection, especially in sectors where employees are exposed to hazardous airborne particles. Wearing the right respiratory protection equipment (RPE) is essential to preventing major respiratory illnesses associated with everything from dust in construction to hazardous substances in manufacturing. The most significant regulations, classifications, and applications of respiratory […]

Maintaining proper respiratory protection is essential to the health and safety of workers in environments where hazardous substances are present. A PPE compliance audit ensures that the right respiratory protective equipment (RPE) is being used, that it’s effectively maintained, and that your business is compliant with UK regulations.

This guide walks you through the steps to conduct a thorough PPE compliance audit for respiratory protection, ensuring the safety of your workforce and compliance with UK health and safety regulations.

- Page Contents

- Step 1: Review Applicable Regulations and Standards

- Step 2: Assess Workplace Hazards

- Step 3: Implement Controls to Reduce Hazards

- Step 4: Evaluate RPE Selection

- Step 5: Check Maintenance and Storage Practices

- Step 5: Review Training and Documentation

- Step 6: Monitor Compliance

- XAMAX®: Your Partner for PPE Compliance

- Conclusion

Step 1: Review Applicable Regulations and Standards

The first step in a PPE compliance audit is to ensure your business is adhering to all relevant UK regulations and industry standards for respiratory protection.

The Legal Framework

Respiratory protection falls under several key regulations, including:

- Control of Substances Hazardous to Health (CoSHH) Regulations 2002

- Personal Protective Equipment (PPE) at Work Regulations 1992

- The Management of Health and Safety at Work Regulations 1999

Each regulation outlines the need to assess hazards, reduce risks, select appropriate PPE, and maintain it effectively. During your audit, cross-check your respiratory protection practices with these regulations to ensure full compliance.

Step 2: Assess Workplace Hazards

The next step is to identify potential hazards that may require respiratory protection. Your risk assessment should consider:

- The presence of dust, fumes, mists, vapours, or gases.

- Airborne biological agents (e.g., spores or bacteria).

- The concentration levels of these substances.

Once the hazards have been identified, document these risks and determine the level of protection required to prevent harm to workers.

Step 3: Implement Controls to Reduce Hazards

This is arguably the most important step in creating a safe working environment.

Before selecting respiratory protection equipment (RPE), it is vital to determine if the hazards highlighted in Step 2 can be reduced or avoided using different control methods.

The goal is to reduce exposure to airborne risks by changing work habits or adding extra safety measures. These safety measures, termed as engineering or administrative controls, should always be implemented before relying on PPE.

Engineering Controls

Engineering controls are physical modifications to the workplace that help reduce the presence of hazardous airborne substances. This can include:

- Ventilation Systems: Installing or upgrading general or local exhaust ventilation to remove contaminants from the air. For example, fume hoods in fabrication workshops or dust extraction systems on construction sites.

- Local Exhaust Ventilation (LEV): LEV systems capture contaminants at or near their source, preventing them from spreading throughout the work area.

- Process Enclosures: Enclosing the source of the hazard (e.g., machines or chemical processes) can limit the release of harmful fumes, dust, or vapours into the general workspace.

- Wet Methods: Mainly suitable for working with stone, using water or other liquids to suppress dust generation during tasks like grinding, cutting, or drilling.

These engineering controls help reduce the concentration of airborne contaminants, lowering the overall risk to workers.

Administrative Controls

Where engineering controls cannot fully eliminate the hazard, administrative controls should be implemented to reduce worker exposure. This may include:

- Changing Work Schedules: Rotating workers in and out of high-risk areas to limit the duration of exposure to hazardous substances.

- Adjusting Work Procedures: Modifying how tasks are performed to reduce dust, fumes, or vapours. For example, using tools with dust suppression features or reducing the speed of a process to decrease the amount of airborne contaminants.

- Training: Ensuring employees are aware of safe work practices and understand how to minimise their exposure to hazardous substances.

Monitoring Exposure Levels

It's also important to monitor exposure levels regularly. Conduct air quality testing to determine whether the concentration of harmful substances in the workplace has been sufficiently reduced by the control measures.

If the levels of contaminants are still too high, consider reinforcing existing controls or introducing new ones.

Step 4: Evaluate RPE Selection

Ensure that the RPE currently in use is appropriate for the specific hazards present in your workplace. This evaluation should include:

- Types of RPE: For example, disposable face masks, half-mask respirators, or powered air-purifying respirators (PAPR).

- Protection Levels: Does the RPE provide the correct protection for the airborne contaminants? For example, FFP1, FFP2, or FFP3 masks for dust or vapours.

- Fit Testing: Ensure all RPE fits the users correctly. Regular fit testing must be conducted, especially if workers’ facial characteristics change.

Step 5: Check Maintenance and Storage Practices

Proper maintenance is crucial for ensuring respiratory protection equipment remains effective over time. As part of the audit, check:

- Cleaning and Maintenance: Is equipment regularly cleaned and maintained according to the manufacturer’s guidelines?

- Storage Conditions: Is RPE stored in a clean, dry, and contaminant-free environment? Poor storage can degrade the equipment and reduce its effectiveness.

- Inspection Frequency: Regular inspections are required to ensure that RPE is still functioning properly. All RPE should be checked before and after use.

Step 6: Review Training and Documentation

Workers need to be trained in the correct use of RPE, and this training should be documented. As part of the audit:

- Ensure that all staff who require RPE have undergone adequate training on how to wear, fit, and maintain it.

- Review training records to verify the completion and adequacy of training sessions.

- Document the training and fit testing results for each employee.

Step 7: Monitor Compliance

Once you've completed your audit, set up a system for continuous monitoring of PPE compliance. This involves:

- Regular spot-checks to ensure employees are wearing RPE correctly.

- Monitoring how well equipment is maintained over time.

- Ongoing risk assessments to account for any changes in workplace conditions or hazards.

XAMAX®: Your Partner for PPE Compliance

XAMAX® offers a comprehensive range of certified respiratory protection equipment that meets UK safety standards. Whether you need disposable masks, half-mask respirators, or more advanced systems like PAPRs, we supply high quality equipment from trusted brands.

While XAMAX® doesn’t provide training or auditing services, you can count on us to supply fully compliant PPE.

By choosing a BSIF-registered safety supplier like XAMAX®, you’re ensuring that your workforce is protected by top-quality safety equipment designed to meet the most stringent UK regulations.

Conclusion

A PPE compliance audit for respiratory protection is essential for safeguarding your workforce and ensuring compliance with UK health and safety regulations.

By thoroughly reviewing regulations, assessing workplace hazards, implementing controls to reduce risks—such as ventilation or local extraction—evaluating RPE selection, ensuring proper maintenance, and providing training, you can effectively protect your employees.

Regular audits help mitigate the risks of long-term illnesses and workplace accidents caused by poor air quality. By actively reducing hazards and maintaining compliance, your business fosters a safer work environment.

Need assistance with respiratory protection solutions? Contact XAMAX® today to explore how we can support your compliance needs.

Maintaining proper respiratory protection is essential to the health and safety of workers in environments where hazardous substances are present. A PPE compliance audit ensures that the right respiratory protective equipment (RPE) is being used, that it’s effectively maintained, and that your business is compliant with UK regulations. This guide walks you through the steps […]

Choosing the appropriate Respiratory Protective Equipment (RPE) for your sector is vital for protecting workers from harmful dusts, gases, and fumes. Different industries pose unique risks, and understanding what kind of protection is required is key.

In this article, we'll explain how to choose appropriate respiratory equipment for different jobs, to make sure your workforce remains safe and in compliance with all safety standards.

- Page Contents

- Why Respiratory Protection is Important

- Types of Respiratory Hazards

- Choosing the Right Respiratory Protection

- Industry-Specific Respiratory Protection

- XAMAX®: Your Partner for Respiratory Protection

- Conclusion

Why Respiratory Protection is Important

In many sectors, workers are at risk of inhaling harmful dust, fumes, or gases. These substances can have negative health effects such as lung disease, breathing difficulties, and even cancer.

By providing the right RPE, you can help protect your employees from these hazards while also ensuring that your company meets legal safety requirements, such as those outlined in the Control of Substances Hazardous to Health (CoSHH) regulations.

Types of Respiratory Hazards

There are several types of respiratory hazards that workers may face. These include:

- Dust: Tiny particles from materials like wood, metal, asbestos, or stone that can damage the lungs.

- Gases and vapours: Chemicals that can be harmful if breathed in, such as those present when spray painting.

- Fumes: Hot vapours that cool and form fine particles, often created by processes like soldering or welding.

- Mists: Tiny droplets of liquid in the air, such as from spraying chemicals or pesticides.

Each of these hazards requires different types of RPE to ensure workers are properly protected.

Choosing the Right Respiratory Protection

To be certain you have chosen the correct RPE, you need to consider:

- The hazard: What substances are in the air? Are they dust, fumes, gases, or mists?

- The concentration of the hazard: How much of the substance is present in the air? Higher levels need more protection.

- Duration of exposure: How long will the worker be exposed to the hazard?

- Fit and comfort: The RPE must fit the wearer correctly. If it’s uncomfortable or doesn’t fit well, workers may not wear it properly, reducing its effectiveness.

There are different types of RPE to choose from:

- Disposable masks (like FFP1, FFP2, and FFP3 masks) are great for short-term or low-level dust protection.

- Half-face respirators provide a higher level of protection and can be fitted with different filters depending on the hazard.

- Full-face respirators cover the eyes and face as well as the mouth and nose, offering full protection from harmful substances.

Industry-Specific Respiratory Protection

Different industries have different respiratory protection needs. Here are some examples:

Construction

Construction workers are frequently exposed to dust from materials such as cement, wood, and brick, as well as fumes from equipment and chemicals.

FFP2 or FFP3 dust masks are often recommended for protection against small dust particles on construction sites, while half-face respirators with P3 filters are suitable for higher-risk environments, such as those involving asbestos.

Manufacturing

In manufacturing, especially metalworking, welding, and cutting, workers are exposed to metal fumes, gases, and vapours. Full-face respirators are often required, especially when working in confined spaces where the concentration of harmful gases is higher.

Respirators with gas filters like A2P3 are suitable for protection against both gases and dust.

Engineering and Fabrication

Welders, fabricators, and metalworkers are frequently exposed to harmful metal fumes and vapours.

Welding aluminium creates microscopic particles of aluminium, aluminium oxide, and other metals contained in aluminium alloys, most notably copper, zinc, magnesium, silicon, manganese, and lithium. These microscopic particles can be inhaled deeply into the lungs before entering the circulation and travelling throughout the body.

Ozone is particularly hazardous and has been found to increase the risks of dementia and cognitive decline.

Powered air-purifying respirators (PAPR) are ideal for these roles, as they supply clean air while filtering out dangerous particles and fumes, offering more comfort for longer tasks.

Agriculture

Farmers and agricultural workers need protection from pesticides, fertilisers, and dust from crops and soil. Half-masks are recommended for handling organic dusts and vapours. P2 or P3 filters filters are essential when working with hazardous chemicals like pesticides.

Ensure workers are fitted with the right filters for both gases and particulates.

Chemical Processing

In industries where workers handle dangerous chemicals, such as oil refineries or pharmaceutical plants, the risk of inhaling toxic fumes or vapours is high.

Full-face respirators with A2P3 filters or self-contained breathing apparatus (SCBA) may be required, depending on the type and concentration of chemicals present.

XAMAX®: Your Partner for Respiratory Protection

At XAMAX®, we provide a wide range of high-quality respiratory protection equipment to suit the needs of various industries. As a BSIF (British Safety Industry Federation) registered supplier, we ensure that all our products meet UK safety standards, helping you stay compliant and protected on the job.

From disposable dust masks to reusable half-face respirators and filter cartridges, we supply only trusted brands known for their durability and effectiveness. Whether you need respiratory protection for construction, manufacturing, or chemical handling, XAMAX® is your go-to supplier for reliable, compliant PPE.

For more information on our products, get in touch with our team.

Conclusion

Choosing the right respiratory protection for your industry is crucial to keeping your workers safe and healthy.

By understanding the types of respiratory hazards and selecting the appropriate RPE, you can reduce the risk of serious health problems.

From construction sites to chemical plants, each industry has unique respiratory protection needs, and XAMAX® are here to help you meet them.

Choosing the appropriate Respiratory Protective Equipment (RPE) for your sector is vital for protecting workers from harmful dusts, gases, and fumes. Different industries pose unique risks, and understanding what kind of protection is required is key. In this article, we’ll explain how to choose appropriate respiratory equipment for different jobs, to make sure your workforce remains safe and […]

Ensuring that your lungs are properly protected at work is critical, especially if you work in an industry where airborne hazards are widespread. Dusts, fumes, gases, and vapours can all have major health consequences if inhaled over time. This is why Respiratory Protective Equipment (RPE) is so essential in many workplaces.

In this guide, we’ll cover why respiratory PPE is important, the key industries where it’s needed most, and how to choose the right protection for the job.

- Page Contents

- Why Is Respiratory Protection Important?

- Key Industries That Require Respiratory Protection

- Choosing the Right Respiratory PPE

- Common Workplace Respiratory Diseases

- XAMAX®: Your Trusted Supplier for Respiratory PPE

- Conclusion

Why Is Respiratory Protection Important?

When hazardous particles, gases, or vapours are inhaled over time, they can have serious health consequences. This includes chronic respiratory conditions such as asthma, COPD, lung cancer, and other potentially lethal ailments.

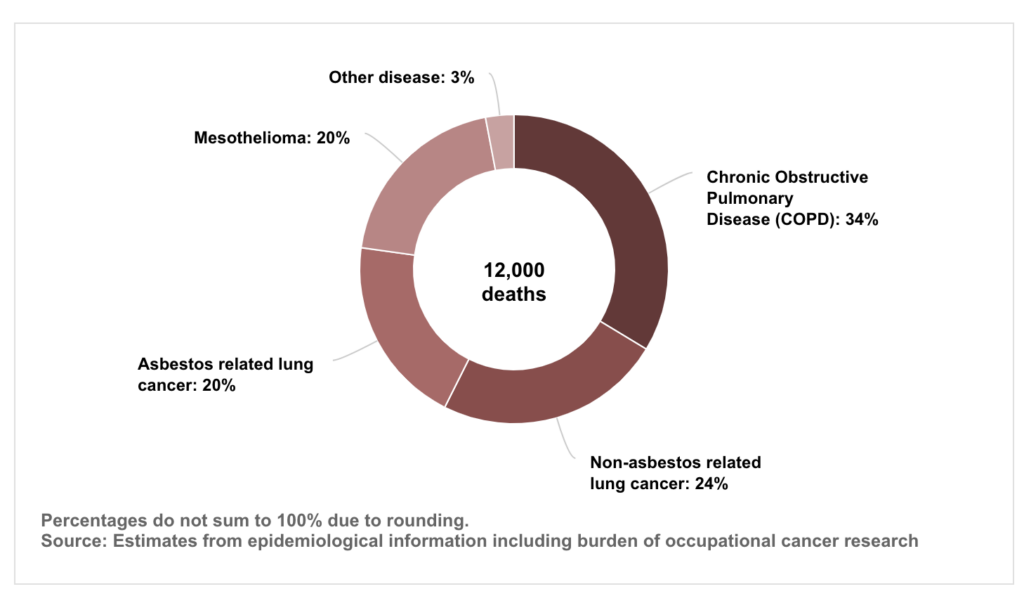

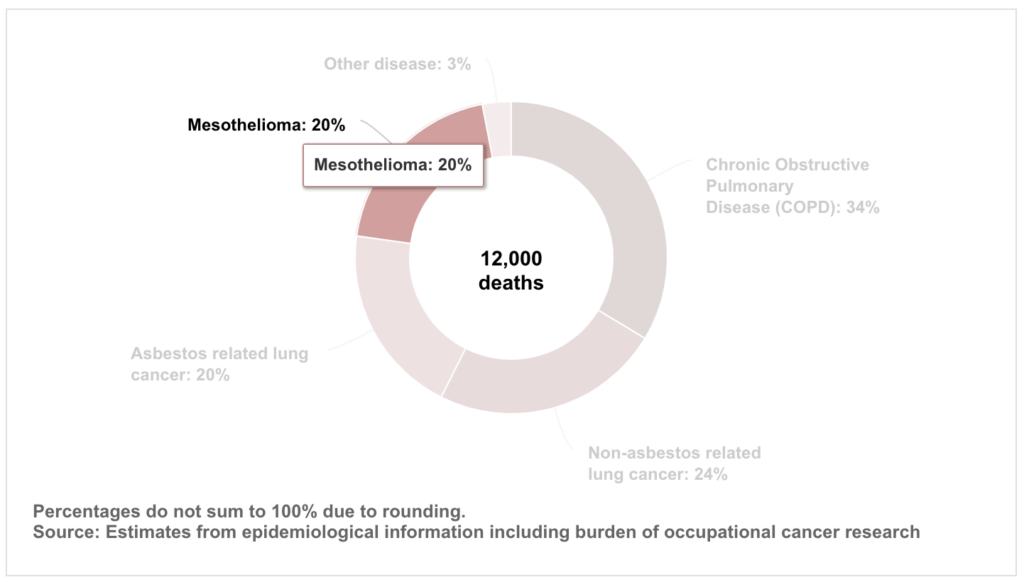

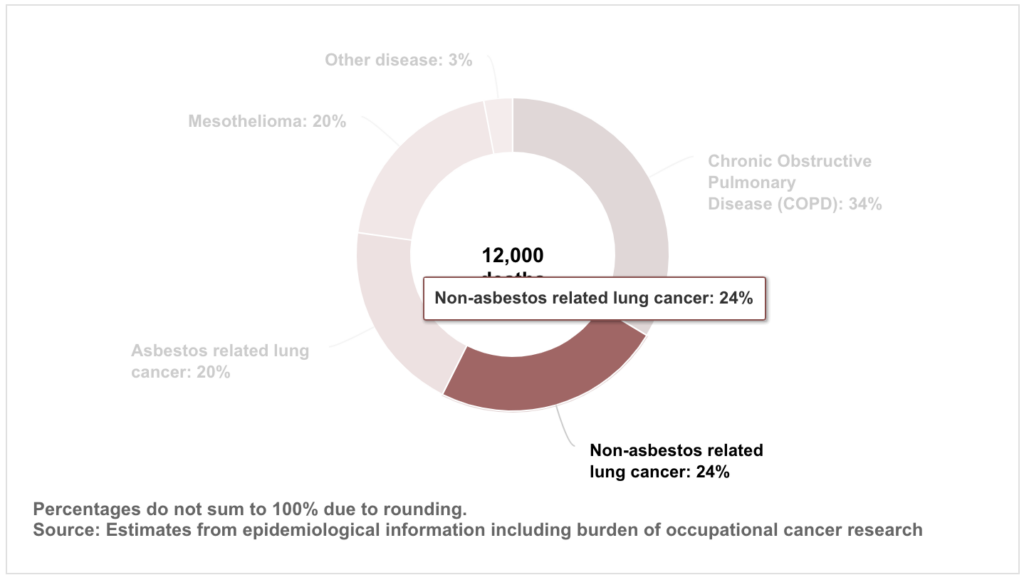

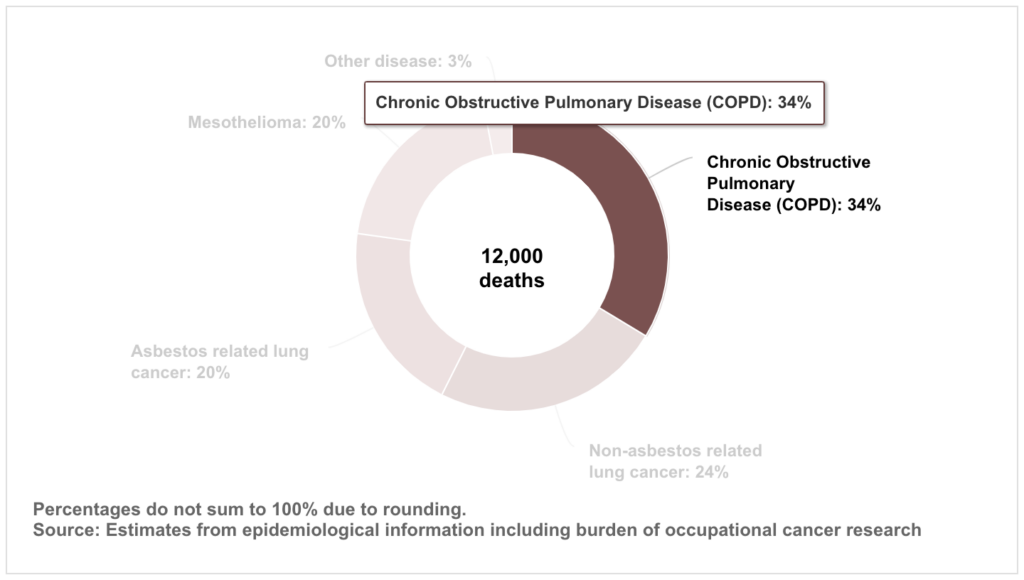

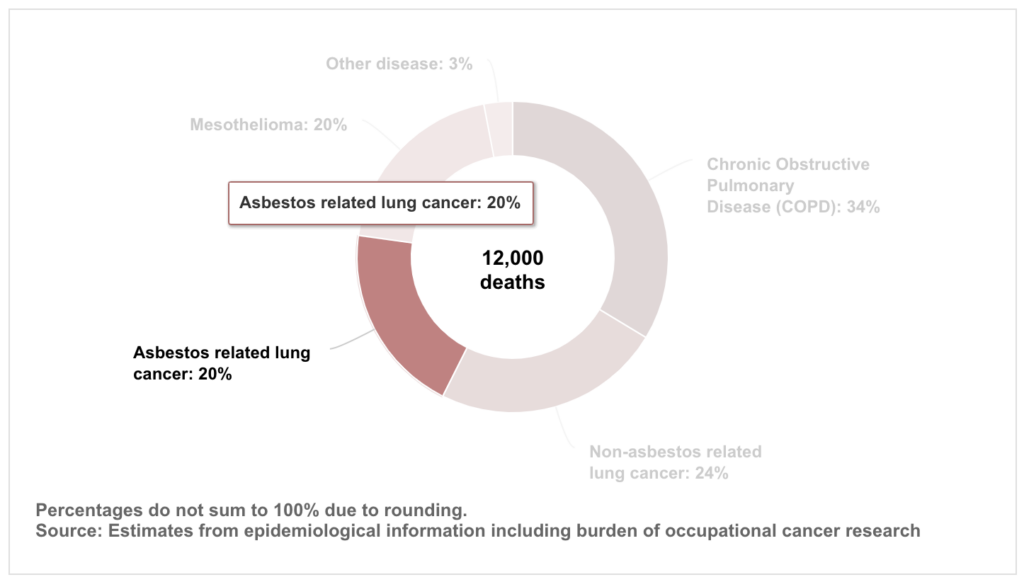

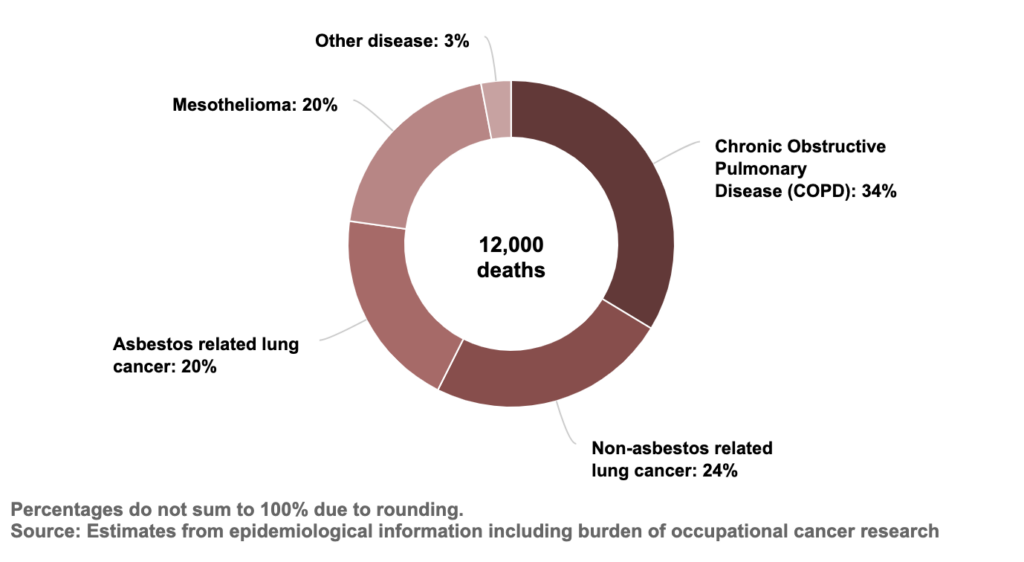

In the UK alone, 12,000 deaths each year are linked to work-related respiratory diseases. Exposure to hazardous substances in the workplace is often a major cause. This is why employers are required by law to ensure workers have the right protection when exposed to these kinds of dangers.

Wearing suitable respiratory PPE helps to minimise the risk of breathing in these harmful substances, preventing long-term illness and even saving lives.

Key Industries That Require Respiratory Protection

RPE is an appropriate form of PPE in many different sectors, making the choice of RPE both easy and somewhat difficult. RPE should be purchased based on the specific requirements of the job in hand, which can be determined by the type of industry you're working in.

Construction

Construction workers face a range of airborne hazards such as dust from cutting, drilling, or demolishing materials like wood, concrete, and plaster. Exposure to silica dust, for instance, can cause silicosis—a serious lung disease that affects thousands of workers each year. Asbestos exposure, often found in older buildings, is another major concern in this industry.

Common Respiratory PPE: FFP3 masks, half-face respirators with P3 filters.

Manufacturing

Many manufacturing processes release dangerous fumes, dust, and gases into the air, particularly in sectors like metalworking, chemicals, and plastics. Inhaling these substances without protection can lead to occupational asthma and other long-term lung diseases.

Common Respiratory PPE: FFP2 or FFP3 masks.

Agriculture

Farming and agriculture often expose workers to organic dusts, pesticides, and fertiliser chemicals that can be harmful if inhaled. Respiratory diseases like farmer’s lung, caused by inhaling dust from hay or grain, are all too common.

Common Respiratory PPE: FFP2 masks, half-face respirators with chemical filters.

Waste Management and Recycling

Those working in waste management or recycling are often exposed to bio-aerosols, dust from waste materials, and hazardous fumes from chemicals. These can cause a range of respiratory conditions, from mild irritation to serious lung diseases.

Common Respiratory PPE: FFP3 dust masks, full-face respirators for chemical exposure.

Engineering and Fabrication

In welding, soldering, and metal fabrication, workers are exposed to dangerous fumes that can lead to metal fume fever and other chronic respiratory conditions. Proper respiratory protection is essential to prevent inhalation of hazardous fumes and gases.

Common Respiratory PPE: Half-face respirators with P3 or gas filters, FFP2 masks.

Choosing the Right Respiratory PPE

Selecting the right respiratory PPE for your industry depends on the type and level of exposure. It's crucial to carry out a thorough risk assessment of your work environment to identify hazards. The type of mask or respirator will depend on factors such as:

- Particle size: For dust and smaller particles, FFP1, FFP2, or FFP3 masks are commonly used.

- Toxicity level: In environments with toxic gases or vapours, such as chemicals or fumes, a respirator with the appropriate filter (e.g., P3 for asbestos) is essential.

- Comfort and duration of wear: For longer shifts or high-exertion tasks, powered air-purifying respirators (PAPR) may offer better comfort and safety.

Always ensure that the respirators meet UK safety standards and are tested regularly to ensure they continue to provide the necessary level of protection.

Common Workplace Respiratory Diseases

Workplace exposure to harmful airborne pollutants can cause a variety of respiratory diseases, some of which may be serious and life-threatening. These are the most common respiratory disorders that workers are at risk of contracting.

Mesothelioma

Mesothelioma is a rare but deadly form of cancer that develops in the thin layer of tissue surrounding the lungs (pleura). It is almost exclusively caused by exposure to asbestos, a material commonly found in older buildings.

The disease has a long latency period, meaning symptoms may not appear until decades after exposure. Unfortunately, mesothelioma is usually diagnosed at an advanced stage, with limited treatment options and a poor prognosis.

Fatality rate: Extremely high, with an average life expectancy of 12 to 21 months after diagnosis.

Lung Cancer

Workplace exposure to carcinogens such as asbestos, silica dust, and diesel exhaust fumes may result in lung cancer, which is one of the most serious kinds of occupational cancer. Symptoms often include a chronic cough, chest pain, and shortness of breath.

The earlier lung cancer is detected, the better the odds for successful treatment; yet, it remains the primary cause of death among workers exposed to hazardous substances.

Fatality rate: High; lung cancer accounts for over 35,000 deaths annually in the UK.

Chronic Obstructive Pulmonary Disease (COPD)

Chronic Obstructive Pulmonary Disease (COPD) is a group of lung conditions, including emphysema and chronic bronchitis, that make it difficult to breathe. It is often caused by long-term exposure to dusts, fumes, and chemicals, particularly in industries like construction, manufacturing, and mining.

COPD is a progressive condition, meaning it gets worse over time and severely impacts a person's ability to live a normal life.

Fatality rate: Moderate to high; COPD is a leading cause of death worldwide.

Silicosis

Silicosis is a lung disease caused by inhaling fine particles of silica dust, commonly found in industries such as construction, mining, and masonry. The dust scars the lungs, leading to breathing difficulties, chest pain, and increased susceptibility to lung infections.

Although it can take years for symptoms to develop, the damage is permanent, and there is no cure once it progresses. In severe cases, silicosis can lead to respiratory failure or lung cancer.

Fatality rate: Moderate; silicosis can be managed if caught early, but severe cases can be life-threatening.

Occupational Asthma

Occupational asthma is caused by exposure to allergens or irritants in the workplace, such as dust, chemicals, fumes, and gases.

Workers in industries like manufacturing, cleaning, and agriculture are particularly at risk. Symptoms include wheezing, coughing, and shortness of breath, and they typically worsen with continued exposure.

Although asthma can be managed with medication, severe cases can significantly impact a worker's quality of life.

Fatality rate: Low, but it can be severe if left untreated or exposure continues

Farmer’s Lung

Farmer’s lung is an allergic reaction caused by inhaling dust from mouldy crops like hay, grain, or straw. This condition leads to inflammation of the lungs and can cause flu-like symptoms, including cough, fever, and shortness of breath.

If exposure continues, it can cause chronic lung damage and long-term respiratory issues.

Fatality rate: Low, but chronic exposure can lead to irreversible lung damage

Asbestosis

Asbestosis is a chronic lung condition caused by prolonged exposure to asbestos fibres. It results in scarring of the lung tissue, leading to coughing, shortness of breath, and, in severe cases, respiratory failure.

While the condition itself is not cancerous, it significantly increases the risk of developing lung cancer and mesothelioma.

Fatality rate: Moderate to high, as it can severely impact lung function and is often a precursor to more serious diseases.

Pneumoconiosis

Pneumoconiosis is a term used to describe a group of lung diseases caused by inhaling mineral dust, including coal dust, silica, and asbestos.

The disease leads to scarring of the lung tissue, which reduces lung capacity and causes breathing difficulties. Coal miners are especially at risk of developing coal workers' pneumoconiosis, commonly known as "black lung" disease.

Fatality rate: Moderate; while manageable with treatment, advanced cases can lead to respiratory failure.

XAMAX®: Your Trusted Supplier for Respiratory PPE

XAMAX® understand the critical importance of respiratory protection in the workplace. As a BSIF-registered safety supplier, we ensure that all the respiratory PPE we supply meets UK safety standards, providing peace of mind for both employers and employees.

Whether you’re in construction, manufacturing, or any other industry, we offer a wide range of high-quality PPE designed to keep your workforce safe.

From FFP1, FFP2, and FFP3 disposable masks to reusable half-mask respirators, XAMAX® has the PPE you need to ensure compliance and protection.

Get in touch with us today to discuss your specific needs, and we’ll help you find the right solutions for your business.

Conclusion

Ensuring the safety of your lungs in the workplace is critical, especially in areas where airborne hazards are common. Respiratory PPE is critical for protecting workers from hazardous dust, fumes, and gases, that can cause major health problems over time.

By understanding the risks in your industry and choosing the correct respiratory protection, you can help to safeguard your health and the well-being of your workforce.

Ensuring that your lungs are properly protected at work is critical, especially if you work in an industry where airborne hazards are widespread. Dusts, fumes, gases, and vapours can all have major health consequences if inhaled over time. This is why Respiratory Protective Equipment (RPE) is so essential in many workplaces. In this guide, we’ll cover […]

A recent survey found that nearly one in four construction workers in the UK may be exposed to asbestos, which places them at a higher risk of contracting terminal illnesses later in life, despite the fact that asbestos has been banned since 1999.

The survey's findings plus the fact that there are potentially half a million buildings around the UK still containing asbestos fibres adds to the trend that Britons have the world's highest chance of dying from mesothelioma, an extremely deadly form of cancer.

- Page Contents

- What Is Asbestos

- Why Was Asbestos Banned?

- Who Is At Risk?

- How Do You Protect Against Asbestos?

- Conclusion

What is Asbestos?

"Asbestos" is a catch-all term used to refer to 6 naturally occurring silicate minerals that have been used by Humans for over 4500 years. The 6 Asbestos minerals are:

- Chrysotile

- Crocidolite

- Amosite

- Tremolite

- Anthophyllite

- Actinolite

All these minerals are composed of long and thin fibrous crystals being composed of many microscopic fibrils. These fibrils can be released into the atmosphere when disturbed.

Asbestos is a known health hazard, and use of it as a building material is now banned in many countries as inhalation of the fibrils can lead to various lung conditions

Crocidolite and Amosite, also known as blue and brown asbestos, are the two most dangerous forms and their use was banned in 1985. Chrysotile, also known as white asbestos, was banned in 1999 except for a small number of specialised uses.

Why was Asbestos Banned?

Asbestos was banned after research found it was responsible for several fatal diseases, including:

- Fibrosis of the lungs - scarring which can cause progressive shortness of breath and can be fatal in severe cases.

- Lung Cancer.

- Pleural thickening - the lining of the lungs (pleura) swells, which can squeeze the lungs and cause shortness of breath and discomfort in the chest.

- Mesothelioma - cancer of the tissue that covers many organs. The most common area affected is the lining of the lungs and chest cavity.

IMPORTANT TO NOTE: Just being near or inside a building containing asbestos in its structure does NOT put you at immediate risk of the above problems. You need to be in a position to inhale asbestos dust fibres. See more on who is at risk further down the page.

In particular, mesothelioma is an incurable disease. Although catching any cancer before it reaches an advanced stage can improve the life expectancy of a mesothelioma patient, long-term survival is extremely rare.

The average life expectancy is between 12 and 21 months, with approximately 40 percent of patients living past one year and only nine percent living beyond five years.

The UK is said to possess one of the highest rates of mesothelioma in the world - a statistic which has generally been attributed to the fact that the UK government banned asbestos usage long after other countries did.

Who is At Risk?

Asbestos can still be found in any building built or refurbished before 2000, meaning that although it's been banned for decades, it is still affecting people today.

The most recent statistics for mesothelioma caused by past exposure to asbestos, show 2,257 people died from the disease in 2022. This is slightly lower than the 2,290 deaths in 2021, and substantially lower than the average of 2,529 deaths per year over the period from 2012 to 2020

Construction workers and people who worked with trains or ships prior to the 1980s, whether it was in the rolling stock manufacturing industry, shipbuilding industry or served aboard one, are at the highest risk because of asbestos being so prevalent in older buildings, older trains and ships. Other occupations at high risk include:

- HVAC engineers

- Plasterers

- Roofing contractors

- Demolition crews

- Railway workers

- Painters and Decorators

- Pipe fitters

- Maintenance

- Carpenters

- Joiners

- Plumbers

- Electricians

- Boilermakers

- Teachers (particularly those who work in old or renovated buildings)

How to Protect Your Workers From Asbestos Exposure

Although asbestos has been banned since 1999, experts have estimated that around 90,000 people will have died between 1970 and 2050, which is when the UK's asbestos epidemic is said to have played itself out. That is why you need to take action to protect your workers.

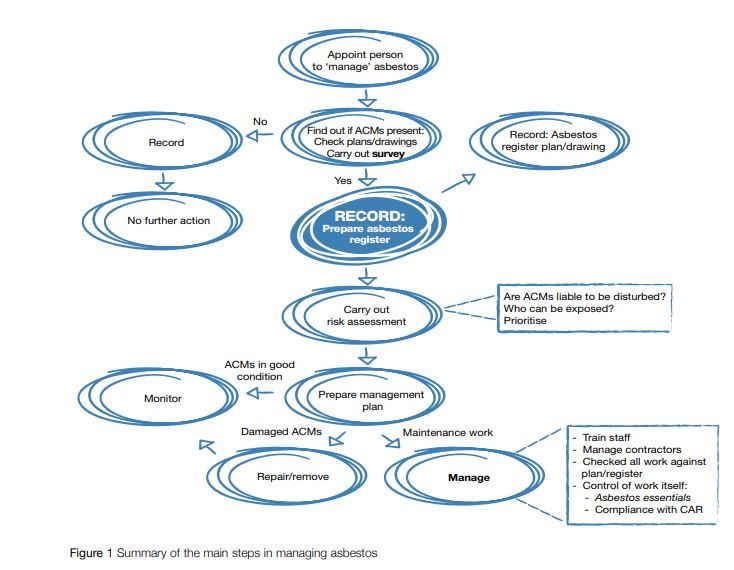

Conduct Risk Assessments

Important To Note: The actual steps of performing an Asbestos risk assessment are quite involved and beyond the scope or authority of this article and author - we cannot offer advice here due to the specialist nature of the risks. However, you can find everything you need to know in this Asbestos Survey Guide from HSE in a downloadable PDF format.

You will already know how important it is to conduct risk assessments and key safety checks before you start work, but ensure that you always consider asbestos as part of the possible health risks. Those responsible for the building, for example, are legally required to provide you with information on the location and the materials.

If there are any asbestos-containing materials, they need to be identified before the work starts. You then need to decide whether these materials need to be handled by a specialist asbestos removal team or to consult the health and safety representative, if there is one, about the appropriate control measures that should be taken.

If you are not sure about any materials, ensure they are tested as soon as possible by a specialist laboratory.

Train Workers to Know the Risks and Precautions They Need to Take

Ensure you train your workers on the risks of asbestos and instruct them on what to do if they encounter asbestos-containing materials.

For example, they should:

- Keep the material damp while they work on it.

- Use hand tools, not power tools which create more dust.

- Use personal protective equipment (PPE) such as respirators, disposable coveralls, goggles etc

- Clean up as they work to prevent waste piling up.

- Clear up asbestos dust using "Type H" vacuum cleaners or damp cloths.

- Wash their hands and face when they are taking a break from work or have finished.

- Placing asbestos waste in a sealed, labelled container before disposing of the debris in the correct manner.

If your team encounter any hidden materials which may contain asbestos, ensure that they stop work immediately and get advice. Identifying asbestos-containing materials isn't easy and you may need to get it sent off to specialist laboratories.

These steps will help to reduce, control and prevent asbestos exposure to the lowest levels possible.

Provide the appropriate personal protective equipment (ppe)

Make sure that you provide your workers with the appropriate protective clothing and equipment before they start work. For example, respirators and protective gloves can reduce exposure to asbestos.

Make sure that you keep on top of PPE maintenance by regularly inspecting equipment for signs of damage and replacing them when necessary. As well as providing PPE, ensure that your staff are trained on how to use equipment and clothing in the safest way possible.

We recommend speaking to a BSiF Registered Safety Supplier such as XAMAX® to ensure the PPE items you provide meet required safety standards.

Respiratory protection must meet at least FFP3 standards. Dust masks or Half Face masks with a P3 rating are good enough, however a full face mask covering the eyes is recommended by HSE.

These Disposable Masks meet the minimum standards. Always dispose of the mask after removing:

These Half Masks and filters meet the minimum standards. Always clean the mask properly after removing:

Don;t forget that any respiratory protection should fit the wearer correctly.

Coveralls for work with asbestos must meet category 3 standards. Within CE category 3 there are several 'types' of coverall:

- Type 2 EN 943:1995 - non gas tight suits which retain a positive internal pressure to prevent the ingress of dusts, liquids or vapours

- Type 5 EN ISO 13982 -1 - protective clothing for use against solid particulate chemicals

- Type 6 EN 13034 - reduced spray suits, suitable for protection against hazardous sprays and splashes as fine droplet, non directional sprays

These disposable coveralls meet EN ISO 13982-1 and EN 13034 and are suitable for working with Asbestos.

Eye, Ear, Foot and Hand protection must meet the usual standards for PPE.

Conclusion

Asbestos might have been banned for 20 years, but it is known as the killer that still surrounds us. With many buildings still containing traces of asbestos, it is important that you and your team are always alert when it comes to working with materials that may contain the mineral.

Disclaimer

Any product listed above is added to this article for informational purposes only. No guarantees of suitability for any task of any kind is implied and nothing in this article constitutes a recommendation. Product adherence to safety standards are the responsibility of the manufacturer. It is the responsibility of the user's employer to ensure the safety of the worker.

A recent survey found that nearly one in four construction workers in the UK may be exposed to asbestos, which places them at a higher risk of contracting terminal illnesses later in life, despite the fact that asbestos has been banned since 1999. The survey’s findings plus the fact that there are potentially half a […]

Here is everything you need to know about dust mask ratings - the same safety standards are used for respirator ratings and the specifications of face masks. After reading, you should know the different dust mask protection levels and the rating system used in respiratory PPE before you choose a dust mask for work.

You should also have a good idea of which dust mask or face mask rating you will require for the job you are doing and the dust protection you need.

- Page Contents

- What Is A Dust Mask For?

- The Safety Acronyms Used

- Why You Should Wear A Dust Mask

- When it comes to your health & safety, it is better to be safe than sorry.

- A quick guide to these three types of dust mask: ffp1, ffp2, ffp3 - the differences

- How to choose between mask ratings

- Maintenance of your respiratory protection

- Our pick of the best dust masks for work

- XAMAX®: Your Trusted Source for Dust Mask and Respiratory Protection

- Conclusion

What Is A Dust Mask For?

Silly question, but we need to start somewhere...

Disposable or half-face dust masks offer respiratory protection against particulate hazards and airborne particles like dusts (anything from wood dust to brick dust to household dusts), powders and aerosols (aka: Aqueous Fog). That is, they filter out bad stuff from the air you breath so you don't inhale poisons or hazardous dust particulates.

Dust masks are vital for a range of industries: construction, agricultural, pharmaceutical, and even for your DIY projects at home. The FFP1, FFP2, FFP3 ratings offer different levels of protection so it is vital you find the correct level of protection you need from a respirator.

The Safety Acronyms Used

Respiratory protection in the form of disposable dust masks come in three respirator ratings: FFP1, FFP2, and FFP3 - FFP stands for "Filtering Face Piece" and the number denotes the level of protection. Many people shorten these acronyms even more as P1, P2 & P3 - but the meaning and level of respiratory protection is the same.

Some people refer to these ratings as respirator codes, respirator filter codes, or respirator grades but we are essentially discussing the very same things.

Each of these types of mask will specify their suitability for the "Occupational Exposure Limit" (OEL) and their "Assumed Protection Factor" (APF).

We use these acronyms throughout this article, and they are in common use within the H&S industry, so you would do well to try and remember them.

When choosing a face mask you need to determine which dust mask ratings you need for your workplace hazards (although your employer should identify the hazards for you and provide the correct PPE) or your home DIY hazard.

Why You Should Wear A Dust Mask

Workers often choose not to wear a dust mask because it feels uncomfortable, men may need to shave everyday (so the mask fits correctly on the face), it may interfere with other PPE (such as their goggles or face screen), other people on site do not wear them and they want to fit in, and many other factors.

However, the risks of not wearing the correct respirator mask with the correct ratings are many and you could develop harmful and life threatening lung conditions.

Remember: The wrong protective face mask is no protection at all

A dust mask can protect you from developing painful coughs, wheezing, shortness of breath, chest tightness, and difficulty breathing - as well as more serious long-term or terminal conditions like lung cancer, chronic obstructive pulmonary disease (COPD) and even mesothelioma.

When it comes to your health & safety, it is better to be safe than sorry.

The mask should be tight fitting, and a fit test should always be performed when fitting a new face mask.

The statistics for respiratory diseases from the 2022/23 HSE report make for sobering reading. There are 12,000 deaths associated with respiratory hazards after long-term exposure and 18,000 estimated new cases of self-reported work-related breathing or lung problems ANNUALLY.

Please do not become a statistic - Choose the right dust mask for the hazards around you.

A quick guide to these three types of dust mask: ffp1, ffp2, ffp3 - the differences

FFP1 Dust Masks

What does a P1 filter protect against?

- Protects against low levels of dust.

- Protects against solid and liquid aerosols.

- Can be used for hand sanding, drilling, and cutting.

- OEL: Protects against materials in concentrations 4x limit.

- APF: Protects against materials in concentrations 4x limit.

FFP2 Dust Masks

What does a P2 filter protect against?

- Protects against moderate levels of dust.

- Protects against solid and liquid aerosols.

- Higher protection than FFP1

- Can be used for plastering and sanding.

- OEL: Protects against materials in concentrations 12x limit.

- APF: Protects against materials in concentrations 10x limit.

FFP3 Dust Masks

What does a P3 filter protect against?

- Protects against higher levels of dust.

- Protects against solid and liquid aerosols.

- Higher protection than FFP1, and FFP2.

- Can be used for handling hazardous powders such as those in the pharmaceutical industry.

- Recommended when in doubt of protection needed.

- OEL: Protects against materials in concentrations 50x limit.

- APF: Protects against materials in concentrations 20x limit.

- Can be used as an Asbestos mask

- Current NHS guidelines stipulate FFP3 face masks for virus and bacterial infection control when the contagion is spread through aerosol (coughs, sneezes etc)

A P3 filter or mask would be the minimum required face mask for chemical fumes, but we would recommend a Half Face Respirator with a P3 Cartridge Filter rather than a disposable dust mask. The same goes for a Dust mask for Asbestos protection - although a disposable P3 dust mask is sufficient, we recommend a half mask with a P3 cartridge or contact us for a full face mask solution.

How to choose between mask ratings

- Identify type and level of contaminant exposure.

- Evaluate airborne hazards in workplace (or workshop).

- Choose mask based on FFP rating.

- Choose a comfortable and convenient mask.

Maintenance of your respiratory protection

- Regardless of the size of your business or company, always perform a PPE respiratory protection audit to make sure everything is as it should be.

- Ensure your respirators are the correct type and safety rating for the intended use.

- Check regularly for damage - do not attempt to repair, replace any damaged masks.

- Discard or clean if breathing becomes affected by blockages or overuse

- Always replace when needed.

- Clean non-disposable equipment daily or as needed in between.

- Keep an inventory of stock, and reorder when low.

- Make sure your PPE meets regulation standards and protects your workers.

Our pick of the best dust masks for work

There are many different types of dust mask, both disposable and reusable, here are some examples of dust masks along with their ratings to give you some idea of what is available to buy.

XAMAX®: Your Trusted Source for Dust Mask and Respiratory Protection

When it comes to choosing dust masks and respiratory protection, it's crucial to source your PPE from a trusted supplier. XAMAX® is a BSIF registered safety supplier, meaning we provide only compliant, high-quality protective equipment. Whether you're working in construction, manufacturing, or other sectors where dust and particulates are a hazard, we offer a range of FFP1, FFP2, and FFP3 dust masks to suit your specific needs.

XAMAX® understand that no two workplaces are the same, which is why we carefully select products that meet the highest standards while also catering to comfort, fit, and durability. Our team ensures that each item meets the latest EN 149 standards for respiratory protection, giving you peace of mind that your team is well-protected.

If you're unsure which level of protection is best for your work environment, our knowledgeable team can guide you to the most suitable product—whether it's for occasional DIY use or for hazardous, high-exposure industries. XAMAX® also offers reliable stock levels and fast, efficient delivery, ensuring you're never without the essential protection your team requires.

You can trust us to keep your workforce safe while maintaining cost-effectiveness and compliance.

Conclusion

Understanding the differences between FFP1, FFP2, and FFP3 dust masks is essential for ensuring proper protection in the workplace. Each rating corresponds to a different level of defence against dust, aerosols, and other hazardous particles, with FFP3 offering the highest protection.

Selecting the right mask based on the hazards present is critical for safeguarding your lungs and preventing long-term health issues such as COPD or mesothelioma.

Not only is it important to choose the correct mask, but regular fit testing and proper maintenance are key to ensuring the effectiveness of the respiratory protection you provide.

Always make sure your team is using dust masks that comply with UK safety regulations and are rated for the specific work they perform.

By making informed decisions about respiratory PPE, you can significantly reduce the risks associated with airborne hazards and ensure a safer, healthier working environment.

Choose XAMAX® for trusted, high-quality respiratory protection that ensures both compliance and safety across a range of industries.

Here is everything you need to know about dust mask ratings – the same safety standards are used for respirator ratings and the specifications of face masks. After reading, you should know the different dust mask protection levels and the rating system used in respiratory PPE before you choose a dust mask for work. You […]

Similar to regular PPE, Respiratory Protective Equipment (or RPE for short) is any facial protective equipment that is specifically designed to protect an individual’s airways from harmful airborne contaminants.

However, in order to rightfully delegate your employees this PPE, not only must you understand the correct respiratory protection ratings for your environment, you must also ensure it is fit for each individual use via a face fit test.

- Page Contents

- What is a Respirator Face Fit Test

- Why Is It Important?

- Who Can Carry Out a Fit Test?

- When Should a Fit Test Be Performed?

- How Do I Perform a Face Fit Test?

- How Do I Document a Face Fit Test?

- And There's More...

- Final Considerations

What is a Face Fit Test?

A Face Fit Test is a certified practice and precaution by HSE (Health and Safety Executive) to ensure that Respiratory Protective Equipment (RPE) is able to provide, at the very least, adequate protection for every employee that requires it.

After making the choices of which type of respiratory protection is needed, a face-fit test checks that the mask or respirator fits the employee's face correctly, leaving no leaks where contaminated air can get through unfiltered. This allows the user to choose the correct size of mask for their face.

Face Fit Testing must be carried out before the respirator or face mask is worn in a contaminated environment with the findings documented.

Why Is Face Fit Testing Important?

Not a day goes by without somebody dying prematurely from a work related lung disease.

My grandfather died of lung cancer caused by his young days working in a cement factory in Yorkshire. His employment was way before safeguards for worker's health and safety were put into practice and enshrined in law. Had he had access to the same training and safety products we all have nowadays, there is no doubt in my mind that he would have lived for longer.

Having access to dust masks or other respiratory protection has changed the life outlook for millions of workers worldwide, but we still need to do better by ensuring all protection actually protects. A poorly fitting respirator is no respirator at all.

Hence, we face fit test to ensure the correct size and type of mask is made available to all works.

Who Can Carry Out a Face Fit Test?

Under UK Legislation, a face fit test has to be conducted by a competent person.

A competent person is defined as someone who is appropriately trained, qualified and experience in doing so. This qualification can be achieved and recognised by accreditation from the Fit2Fit scheme, which was introduced by The British Safety Industry Federation (BSIF) with support from the HSE.

When Should I Do a Fit Test?

A Fit Test should be carried out in the very initial stages of the buying process to ensure that the item of workwear is fit for purpose and in accordance with the Control of Substances Hazardous to Health Regulations 2002.

Employers, like yourself, need to ensure all PPE is in agreement with these regulations by documenting and measuring appropriate risk assessment, control of exposure, health surveillance and incident planning.

In other words, a respirator face fit test is necessary if dust masks or respiration is required.

It is important to note, that any breathing apparatus selected, must be identical to that carried out within the respirator fit test. This concerns the make, model, type, and size, which is specific to each employee.

How Do I Do a Respirator Fit Test?

Once you have selected the protective face mask or respirator you wish to order and have a competent individual to carry out the test, it is time to know how to do one. The Fit Test itself is something that has to be well documented with the necessary details which are retained for inspection.

A Fit Test can be split into two types: a Qualitative Fit Test (QLFT), and a Quantitative Fit Test (QNFT).

Qualitative Fit Test (QLFT)

A qualitative fit test may only be used to fit test:

- Air Purifying Respirators that are used in negative pressure. This fit test is on the basis that they will be used in atmospheres where the potential hazard is 10 times the permissible exposure limit (PEL).

- Tight fit face protection with powered and atmosphere-supplying respirators.

The QLFT results are split into either Pass or Fail depending on the subject’s senses/reactions to the following test agents:

- Isoamyl acetate (simulates a banana smell); only for testing respirators that utilise organic vapor cartridges.

- Saccharin (simulates a sweet taste); can test respirators with a particulate filter of any class.

- Bitrex (simulates a bitter taste); can test respirators with particulate filters of any class.

- Irritant Smoke (prompts a cough reflex); only for testing respirators with level 100 particulate filters.

If any of the above test agents are detected by the subject, then the respirator will not comply with the Control of Substances Hazardous to Health Regulations 2002 (CoSHH).

In order to fairly test the above agents, the following 7 exercises must be conducted for 1 minute each. The exercises are as follows:

- Normal Breathing (1 minute)

- Deep Breathing (1 minute)

- Moving head side to side (1 minute)

- Moving head up and down (1 minute)

- Bending over, or jogging on the spot - if the apparatus does not allow bending at the waist (1 minute)

- Talking (1 minute)

- Normal Breathing Again (1 minute)

Quantitative Fit Test (QNFT)

The more common of the two is the Quantitative Fit Test (QNFT) which is used to fit-test any tight-fitting respirator. It mainly involves using equipment to measure the leakage around the face seal of the breathing apparatus. This test will produce a numerical result defined as a “fit factor” which can be produced from any of the following 3 test protocols:

- Generated Aerosol: uses a non-hazardous aerosol which is generated within the test chamber (i.e. corn oil).

- Condensation nuclei counter (CNC): uses an ambient aerosol and does not require a test chamber to be used.

- Controlled negative pressure (CNP): uses a test that creates a vacuum by temporarily cutting off air/oxygen.

The Quantitative Fit Test uses the same 7 exercises that the Qualitative Fit Test uses with the addition of a ‘grimace’ test which involves the subject smiling or frowning for 15 seconds to test the integrity of the facial seal.

Whilst the Qualitative Fit Test is Pass or Fail, the Quantitative Fit Test is graded on achieving a minimum threshold. The threshold for half-mask respirators is a minimum fit factor of 100, whereas for full-mask respirators it is 500.

How Do I Document a Face Fit Test?

It is important to record any Face Fit Tests you do so that you can prove your PPE is in compliance with UK legislation, should it ever come into question.

The test must be recorded by accredited personnel and concerns the following measures taking place:

Document the following:

- Name of the person tested

- Make, model and size of the facepiece

- Whether the wearer’s own mask, company pool mask or a fit test service’s mask was used

- The test exercises performed during the test

- Fit test method used so either

- Qualitative for filtering facepieces (FFPs, disposable masks) and half masks

- Quantitative for FFPs (disposable masks), half and full face masks Measured fit factor values for each test

- Pass Level used

- Date of the test

- Details of the person carrying out the fit test

- Retain recordings per inspection.

Ensure all employees that are required to wear a respiratory face mask are fit to do so in regards to personal health by completing a medical evaluation.

Is that everything?

By carrying out the respirator fit test you are ensuring that the face protection you are ordering for each employee is fit for purpose and in accordance with UK legislation.

It is your duty as an employer to remind your employees that they must conduct checks on their breathing apparatus for their own safety. The face protection should be a firm and tight fit to the employees face which should not move when in motion and the employees should perform a seal check each time they put on the respirator.

Employees can either perform a positive-pressure check or negative-pressure check depending on their environment.

Positive Pressure

Your employees must block the exhalation valve on a half or full facepiece respirator, or covering the respirator’s surface using your hands, before breathing out. If pressure builds up and is felt within the mask, then the seal is fit and appropriate for workplace use.

Negative Pressure

Your employees must block the intake valve on a half or full facepiece respirator, or cover the respirator’s surface using your hands before breathing in. If no air enters, then the seal is fit and appropriate for workplace use.

It is important to maintain these checks prior to every use as a precaution for any deteriorating facepiece seals.

Be Aware of These Considerations

It is important that when both you and your employees perform their fit tests, that facial hair is kept to an absolute minimum so that results remain accurate and reliable. Any slight facial hair between the seal and the employee’s face can distort test results and lead to potentially unsafe facial equipment by dampening the seal’s effectiveness.

Just because a respirator fits one person, it does not mean it will fit everyone. Similarly, just because one size of one type of respirator fits, it does not mean that all respirators of the same size will fit. The point of Face Fit Testing is to determine the correct size and shape of respirator for each individual worker.

Face Fit Testing also gives some training to the wearer on how to fit their respiration protection effectively and carry out quick tests each time they use it. This improves the function of the mask and improves employee's responsibility for their own health and safety.

Similar to regular PPE, Respiratory Protective Equipment (or RPE for short) is any facial protective equipment that is specifically designed to protect an individual’s airways from harmful airborne contaminants. However, in order to rightfully delegate your employees this PPE, not only must you understand the correct respiratory protection ratings for your environment, you must also […]