The Complete Guide to Respiratory Protection: Regulations, Ratings, and Industry Applications

A key element of workplace safety is respiratory protection, especially in sectors where employees are exposed to hazardous airborne particles. Wearing the right respiratory protection equipment (RPE) is essential to preventing major respiratory illnesses associated with everything from dust in construction to hazardous substances in manufacturing.

The most significant regulations, classifications, and applications of respiratory protection in many sectors are covered in this guide, giving workers and managers the knowledge they need to ensure a safe work environment.

- Page Contents

- Introduction to Respiratory Protection

- Key UK Regulations for Respiratory Protection

- Types of Respiratory Protection

- Respiratory Protection Ratings Explained

- Applications by Industry

- XAMAX®: Why Choose Us?

- Conclusion

Introduction to Respiratory Protection

Respiratory Protective Equipment (RPE) is essential in workplaces where employees are exposed to airborne hazards such dust, fumes, vapours, and gases.

Proper RPE use can help to prevent long-term health issues such as chronic respiratory diseases, lung cancer, and other major disorders.

Workers and employers can ensure effective protection in any hazardous environment by understanding the relevant legislation and protective ratings.

Key UK Regulations for Respiratory Protection

Several regulations govern the use of respiratory protection in the UK. Employers must comply with these rules to ensure the safety of their workers.

Control of Substances Hazardous to Health (COSHH) Regulations

The COSHH Regulations 2002 are one of the most important frameworks that require employers to control exposure to hazardous substances in the workplace. According to COSHH, employers must:

- Assess the risks: Identify the hazardous substances and evaluate the level of exposure.

- Provide adequate RPE: Ensure that the provided respiratory protection is suitable for the work environment.

- Conduct face fit testing: Tight-fitting respirators must be tested for a proper seal on each employee's face.

- Monitor health: Regular health surveillance is required for workers who may develop lung diseases.

Personal Protective Equipment at Work Regulations 1992

The PPE at Work Regulations 1992 mandate that employers must provide suitable personal protective equipment, including RPE, at no cost to the employee. These regulations also require employers to:

- Ensure that PPE is appropriate for the risks involved.

- Maintain and replace the equipment regularly.

- Train employees on the correct usage and limitations of RPE.

British Standards Institution (BSI) Compliance

BSI is responsible for setting standards for the design and testing of PPE. Respiratory protection must comply with BS EN 149, the UK standard for filtering facepieces (FFP), and other relevant standards.

Employers should ensure that all RPE is certified by BSI for protection against specific hazards.

Fit2Fit Accreditation for Face Fit Testing

The Fit2Fit accreditation ensures that those performing face fit tests for tight-fitting respirators are competent. Testing ensures the mask properly seals to the wearer’s face, reducing the risk of inhaling contaminants.

Types of Respiratory Protection

There are several types of RPE, each suited for different hazards and industries. Choosing the right one depends on the level of airborne hazard and the type of work performed.

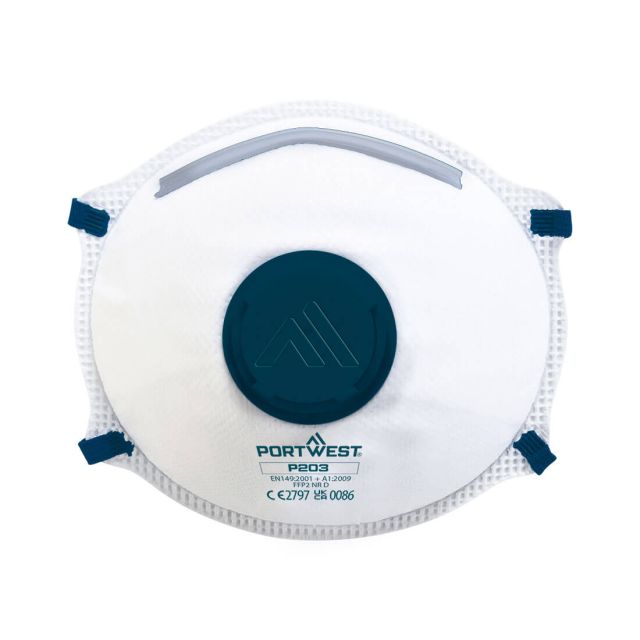

Disposable Dust Masks

These masks, also known as filtering facepieces (FFP), provide protection against dust and non-toxic particles. They are common in construction and light industrial work where low-level dust exposure occurs.

Materials: Typically made from lightweight fabric with integrated particulate filters.

Half-Face Respirators

Half-face respirators cover the nose and mouth, offering protection against dust, fumes, vapours, and some gases. These are suitable for industries dealing with more hazardous airborne particles, such as metalworking or chemical processing.

Materials: Made from silicone or rubber for durability, with replaceable filters.

Full-Face Respirators

Full-face respirators provide a higher level of protection, covering the entire face to protect both the respiratory system and the eyes from exposure to harmful substances. Commonly used in hazardous environments such as chemical plants.

Materials: Made from durable rubber or silicone with replaceable filters.

Powered Air-Purifying Respirators (PAPR)

PAPRs use a battery-powered fan to draw air through filters. These are often used in environments where workers are exposed to toxic fumes, dust, or vapours for extended periods.

Materials: Lightweight and designed for long-term use with advanced filtration systems.

Self-Contained Breathing Apparatus (SCBA)

SCBAs provide breathable air from a tank and are used in environments with little or no oxygen, such as confined spaces or emergency response situations.

Materials: High-strength materials to withstand extreme conditions.

Respiratory Protection Ratings Explained

The level of protection provided by respiratory equipment is measured using specific ratings and assigned protection factors (APF).

FFP1, FFP2, and FFP3 Ratings

These ratings apply to filtering facepieces and represent the level of protection they offer against particulate hazards:

- FFP1: Filters at least 80% of airborne particles. Suitable for light dust environments, such as basic construction tasks.

- FFP2: Filters at least 94% of airborne particles. Suitable for environments with moderate hazards, such as sanding and plastering.

- FFP3: Filters at least 99% of airborne particles. Recommended for high-hazard environments, such as working with asbestos or toxic chemical fumes.

APF (Assigned Protection Factor)

The Assigned Protection Factor (APF) is an important measure for determining the amount of protection provided by respiratory protective equipment (RPE). APF ratings indicate how well the respirator reduces exposure to hazardous substances when worn correctly. The higher the APF, the more effective the protection.

For example, an APF of 10 means that the respirator reduces the user’s exposure to airborne contaminants to 1/10th of the concentration in the surrounding air. An APF of 20 reduces it to 1/20th, and so on. Knowing the APF of a respirator allows employers and workers to make informed decisions about whether the equipment is suitable for the level of hazards present in the workplace.

In the UK, the Health and Safety Executive (HSE) provides guidelines on selecting respirators with appropriate APF levels for different hazardous environments. Different types of RPE, such as filtering facepieces, half masks, and full-face masks, all have varying APF values. It's essential to refer to these ratings when assessing the suitability of respiratory protection for specific tasks.

Applications by Industry

Different industries require different types of respiratory protection depending on the specific hazards present. Here’s a breakdown of common industries and the type of respiratory protection needed:

Construction

Construction workers are often exposed to dust, fumes, and other airborne particles from materials like concrete, brick, and asbestos. FFP3 masks are typically required to protect against these hazards.

Regular fit testing and maintenance are critical to ensure continued protection.

Manufacturing

In industries like metalworking, painting, and chemical processing, workers may be exposed to hazardous fumes and vapours.

Half-face and full-face respirators with appropriate filters are essential to protect workers from harmful gases and chemicals.

Agriculture

Farmers and agricultural workers face risks from dust, pesticides, and animal dander. Disposable FFP2 or FFP3 masks are often used to protect against these particulates, while half-face respirators are useful for chemical applications.

Automotive and Engineering

Workers in automotive repair and engineering are often exposed to dust, solvents, and other chemicals.

Half-face respirators with P2 or P3 filters offer effective protection from inhaling dangerous fumes and particles during tasks such as sanding, welding, and painting.

Mining and Quarrying

Workers in the mining industry are exposed to high levels of dust and sometimes toxic gases. Full-face respirators and PAPRs are commonly used to provide sufficient protection in these hazardous environments.

Woodworking

In woodworking, wood dust is the primary hazard. FFP2 or FFP3 dust masks provide essential protection for workers cutting, sanding, or shaping wood, as these tasks generate fine particulate matter that can be harmful to the lungs.

XAMAX®: Why Choose Us?

When it comes to respiratory protection, you can trust XAMAX® to supply the highest quality PPE that meets UK safety standards.

As a BSIF registered safety supplier, we ensure that every product complies with regulations and is designed to provide maximum protection for your workforce.

Whether you're in construction, manufacturing, or any other industry, XAMAX® offers a wide range of respiratory protection to suit your specific needs.

Protect your team with our industry-leading respiratory protective equipment. Explore our full range of RPE or request a callback for expert guidance on choosing the right RPE for your business.

Conclusion

Respiratory protection is a crucial part of workplace safety, especially in sectors where workers are exposed to air-borne contaminants like dust, fumes, vapours, or gases. Understanding the many forms of RPE, regulatory demands, and appropriate protection ratings enables companies and employees to make educated decisions about their safety.

Employers must comply with requirements set by UK legislation such as COSHH and PPE at Work in order provide proper protection to their employees. Companies can significantly reduce the risk of respiratory infections among their employees by selecting the appropriate respirator, conducting face fit tests, and ensuring regular maintenance.

Whether you need basic dust masks for light construction or advanced PAPRs for chemical plants, selecting the correct RPE is crucial for worker health and safety. Always ensure that your equipment complies with the highest safety standards and is suited for your industry’s specific needs.

XAMAX® are committed to providing BSIF-certified respiratory protection products that meet UK safety standards. Our range includes everything from disposable masks to full-face respirators, ensuring that you have the right protection for any job.