Protecting Your Lungs: The Importance of Respiratory PPE in Different Industries

Ensuring that your lungs are properly protected at work is critical, especially if you work in an industry where airborne hazards are widespread. Dusts, fumes, gases, and vapours can all have major health consequences if inhaled over time. This is why Respiratory Protective Equipment (RPE) is so essential in many workplaces.

In this guide, we’ll cover why respiratory PPE is important, the key industries where it’s needed most, and how to choose the right protection for the job.

- Page Contents

- Why Is Respiratory Protection Important?

- Key Industries That Require Respiratory Protection

- Choosing the Right Respiratory PPE

- Common Workplace Respiratory Diseases

- XAMAX®: Your Trusted Supplier for Respiratory PPE

- Conclusion

Why Is Respiratory Protection Important?

When hazardous particles, gases, or vapours are inhaled over time, they can have serious health consequences. This includes chronic respiratory conditions such as asthma, COPD, lung cancer, and other potentially lethal ailments.

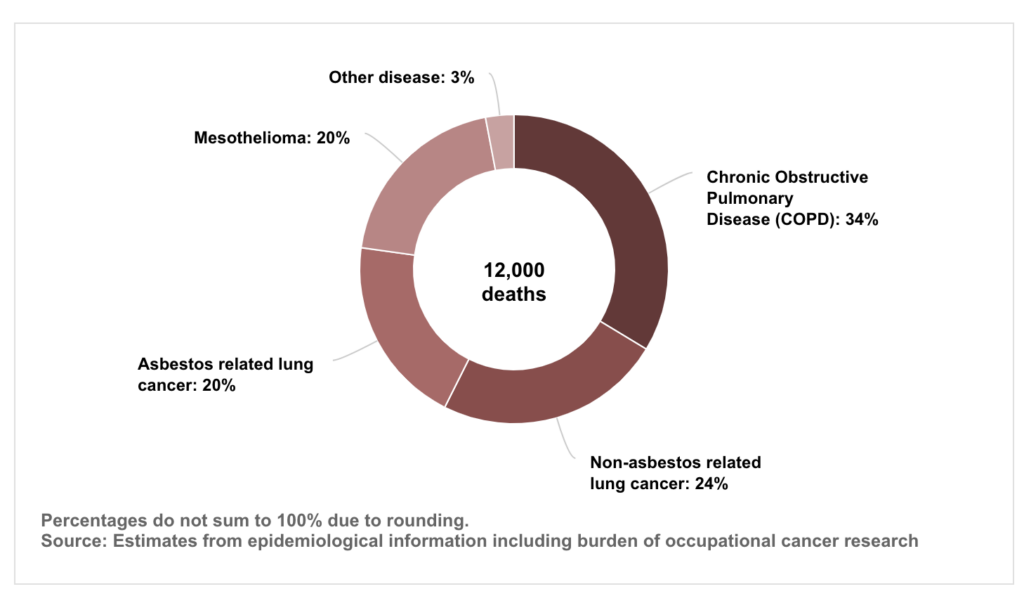

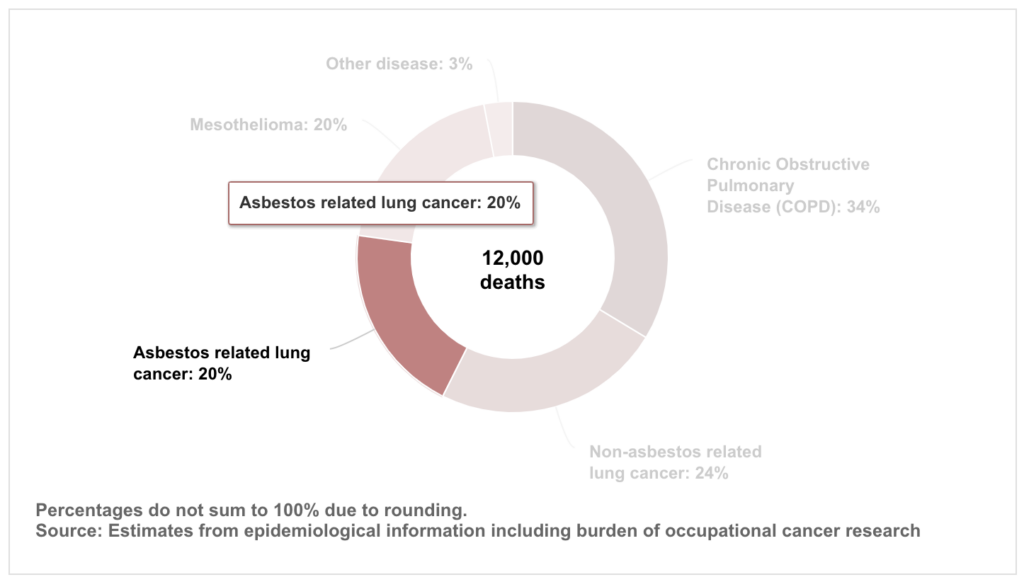

In the UK alone, 12,000 deaths each year are linked to work-related respiratory diseases. Exposure to hazardous substances in the workplace is often a major cause. This is why employers are required by law to ensure workers have the right protection when exposed to these kinds of dangers.

Wearing suitable respiratory PPE helps to minimise the risk of breathing in these harmful substances, preventing long-term illness and even saving lives.

Key Industries That Require Respiratory Protection

RPE is an appropriate form of PPE in many different sectors, making the choice of RPE both easy and somewhat difficult. RPE should be purchased based on the specific requirements of the job in hand, which can be determined by the type of industry you're working in.

Construction

Construction workers face a range of airborne hazards such as dust from cutting, drilling, or demolishing materials like wood, concrete, and plaster. Exposure to silica dust, for instance, can cause silicosis—a serious lung disease that affects thousands of workers each year. Asbestos exposure, often found in older buildings, is another major concern in this industry.

Common Respiratory PPE: FFP3 masks, half-face respirators with P3 filters.

Manufacturing

Many manufacturing processes release dangerous fumes, dust, and gases into the air, particularly in sectors like metalworking, chemicals, and plastics. Inhaling these substances without protection can lead to occupational asthma and other long-term lung diseases.

Common Respiratory PPE: FFP2 or FFP3 masks.

Agriculture

Farming and agriculture often expose workers to organic dusts, pesticides, and fertiliser chemicals that can be harmful if inhaled. Respiratory diseases like farmer’s lung, caused by inhaling dust from hay or grain, are all too common.

Common Respiratory PPE: FFP2 masks, half-face respirators with chemical filters.

Waste Management and Recycling

Those working in waste management or recycling are often exposed to bio-aerosols, dust from waste materials, and hazardous fumes from chemicals. These can cause a range of respiratory conditions, from mild irritation to serious lung diseases.

Common Respiratory PPE: FFP3 dust masks, full-face respirators for chemical exposure.

Engineering and Fabrication

In welding, soldering, and metal fabrication, workers are exposed to dangerous fumes that can lead to metal fume fever and other chronic respiratory conditions. Proper respiratory protection is essential to prevent inhalation of hazardous fumes and gases.

Common Respiratory PPE: Half-face respirators with P3 or gas filters, FFP2 masks.

Choosing the Right Respiratory PPE

Selecting the right respiratory PPE for your industry depends on the type and level of exposure. It's crucial to carry out a thorough risk assessment of your work environment to identify hazards. The type of mask or respirator will depend on factors such as:

- Particle size: For dust and smaller particles, FFP1, FFP2, or FFP3 masks are commonly used.

- Toxicity level: In environments with toxic gases or vapours, such as chemicals or fumes, a respirator with the appropriate filter (e.g., P3 for asbestos) is essential.

- Comfort and duration of wear: For longer shifts or high-exertion tasks, powered air-purifying respirators (PAPR) may offer better comfort and safety.

Always ensure that the respirators meet UK safety standards and are tested regularly to ensure they continue to provide the necessary level of protection.

Common Workplace Respiratory Diseases

Workplace exposure to harmful airborne pollutants can cause a variety of respiratory diseases, some of which may be serious and life-threatening. These are the most common respiratory disorders that workers are at risk of contracting.

Mesothelioma

Mesothelioma is a rare but deadly form of cancer that develops in the thin layer of tissue surrounding the lungs (pleura). It is almost exclusively caused by exposure to asbestos, a material commonly found in older buildings.

The disease has a long latency period, meaning symptoms may not appear until decades after exposure. Unfortunately, mesothelioma is usually diagnosed at an advanced stage, with limited treatment options and a poor prognosis.

Fatality rate: Extremely high, with an average life expectancy of 12 to 21 months after diagnosis.

Lung Cancer

Workplace exposure to carcinogens such as asbestos, silica dust, and diesel exhaust fumes may result in lung cancer, which is one of the most serious kinds of occupational cancer. Symptoms often include a chronic cough, chest pain, and shortness of breath.

The earlier lung cancer is detected, the better the odds for successful treatment; yet, it remains the primary cause of death among workers exposed to hazardous substances.

Fatality rate: High; lung cancer accounts for over 35,000 deaths annually in the UK.

Chronic Obstructive Pulmonary Disease (COPD)

Chronic Obstructive Pulmonary Disease (COPD) is a group of lung conditions, including emphysema and chronic bronchitis, that make it difficult to breathe. It is often caused by long-term exposure to dusts, fumes, and chemicals, particularly in industries like construction, manufacturing, and mining.

COPD is a progressive condition, meaning it gets worse over time and severely impacts a person's ability to live a normal life.

Fatality rate: Moderate to high; COPD is a leading cause of death worldwide.

Silicosis

Silicosis is a lung disease caused by inhaling fine particles of silica dust, commonly found in industries such as construction, mining, and masonry. The dust scars the lungs, leading to breathing difficulties, chest pain, and increased susceptibility to lung infections.

Although it can take years for symptoms to develop, the damage is permanent, and there is no cure once it progresses. In severe cases, silicosis can lead to respiratory failure or lung cancer.

Fatality rate: Moderate; silicosis can be managed if caught early, but severe cases can be life-threatening.

Occupational Asthma

Occupational asthma is caused by exposure to allergens or irritants in the workplace, such as dust, chemicals, fumes, and gases.

Workers in industries like manufacturing, cleaning, and agriculture are particularly at risk. Symptoms include wheezing, coughing, and shortness of breath, and they typically worsen with continued exposure.

Although asthma can be managed with medication, severe cases can significantly impact a worker's quality of life.

Fatality rate: Low, but it can be severe if left untreated or exposure continues

Farmer’s Lung

Farmer’s lung is an allergic reaction caused by inhaling dust from mouldy crops like hay, grain, or straw. This condition leads to inflammation of the lungs and can cause flu-like symptoms, including cough, fever, and shortness of breath.

If exposure continues, it can cause chronic lung damage and long-term respiratory issues.

Fatality rate: Low, but chronic exposure can lead to irreversible lung damage

Asbestosis

Asbestosis is a chronic lung condition caused by prolonged exposure to asbestos fibres. It results in scarring of the lung tissue, leading to coughing, shortness of breath, and, in severe cases, respiratory failure.

While the condition itself is not cancerous, it significantly increases the risk of developing lung cancer and mesothelioma.

Fatality rate: Moderate to high, as it can severely impact lung function and is often a precursor to more serious diseases.

Pneumoconiosis

Pneumoconiosis is a term used to describe a group of lung diseases caused by inhaling mineral dust, including coal dust, silica, and asbestos.

The disease leads to scarring of the lung tissue, which reduces lung capacity and causes breathing difficulties. Coal miners are especially at risk of developing coal workers' pneumoconiosis, commonly known as "black lung" disease.

Fatality rate: Moderate; while manageable with treatment, advanced cases can lead to respiratory failure.

XAMAX®: Your Trusted Supplier for Respiratory PPE

XAMAX® understand the critical importance of respiratory protection in the workplace. As a BSIF-registered safety supplier, we ensure that all the respiratory PPE we supply meets UK safety standards, providing peace of mind for both employers and employees.

Whether you’re in construction, manufacturing, or any other industry, we offer a wide range of high-quality PPE designed to keep your workforce safe.

From FFP1, FFP2, and FFP3 disposable masks to reusable half-mask respirators, XAMAX® has the PPE you need to ensure compliance and protection.

Get in touch with us today to discuss your specific needs, and we’ll help you find the right solutions for your business.

Conclusion

Ensuring the safety of your lungs in the workplace is critical, especially in areas where airborne hazards are common. Respiratory PPE is critical for protecting workers from hazardous dust, fumes, and gases, that can cause major health problems over time.

By understanding the risks in your industry and choosing the correct respiratory protection, you can help to safeguard your health and the well-being of your workforce.