How to Maintain and Store Your Safety Glasses

Eye safety is paramount for jobs where materials, dusts, fluids or gases could be ejected into the air. Over 90% of cases of eye injuries reported could have been prevented with protective glasses. Over 2,000 people suffer each year with an eye injury. If your workplace has deemed that protective goggles or safety glasses are necessary, how do you maintain and store your PPE?

Regulations

It is important that you know the latest PPE regulations. The following regulations apply to eye protection:

EN 166: Requires eye protection in industries with potential eye hazards or anything that is likely to impair or damage vision. There are exemptions for nuclear radiation, x-rays, laser beams and low temperature infrared.

- EN 170: Ultraviolet filters

- EN 171: Infrared filters

- EN 172: Sunglare filters for industrial use

- EN 175: Eye and face protection during welding

Maintenance of Safety Eyewear

Manufacturers must provided instructions of use and care for each specific pair of safety glasses. This includes how to maintain them but a general rule is to clean them daily.

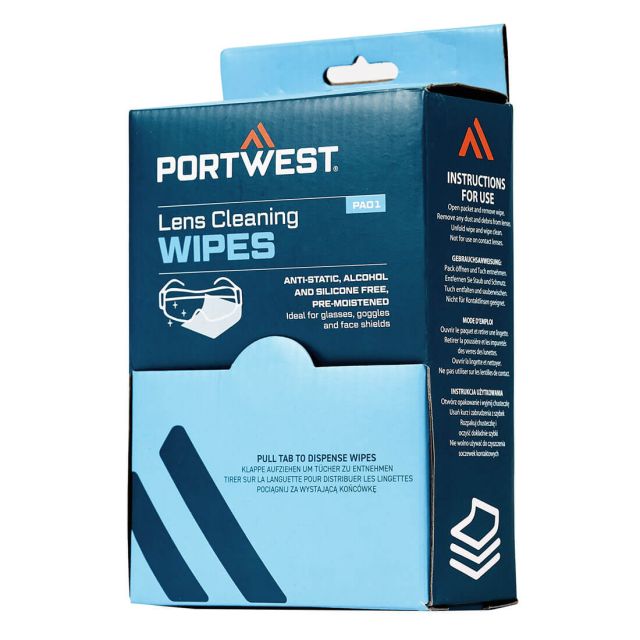

You can blow loose dirt and debris from the lenses, rinse them under running water using detergent or use lens cleaning wipes or sprays. Make sure you store them in a clean dry place after washing.

Avoid rough handling because scratches will impair the vision and weaken the lenses. Safety glasses have quite a long shelf life when compared to other PPE equipment, but only when cared for. Proper maintenance will make sure you get the maximum shelf life.

You can mend your safety goggles providing you replace damaged parts only with the original manufacturer parts to ensure the same safety rating. Scratched or broken lenses cannot be repaired, you must be replace the entire unit.

Storage of Safety Eyewear

You need to store safety spectacles in a case, special bag or a clean and dry place to avoid scratching, falling or being stepped on. Some workplaces have special drawers to store glasses safely in neat rows, other companies provide bags for storing your glasses in. You need to avoid storing your safety glasses in large piles because scratches will impair you vision and safety.

Replacement Rate

As stated, safety glasses have one of the longest lives of any PPE equipment. However, despite their condition you should replace them every 3 years. If you maintain them, your glasses can last up to that 3 year period without incident.

Make sure you replace protective glasses that are damaged, scratched, pitted, broken, bent or ill-fitting. Ill-fitting safety glasses do not protect the wearer.

Correct Fit

To ensure your safety glasses must fit, the eye and bridge size, and temple length vary so your safety glasses need to be individually fitted. Temples should fit comfortable over your ears and the frame should be as close to the face as possible with adequate support on the bridge of the nose. Find the best fit and protection for every worker who requires eye protection.

How to Choose the Best Eyewear for You

You need to choose your safety specs based on the colour of the lens - depending on the industry and comfort.

- Clear lenses provide standard protection

- Amber lenses removes blue light for low-light environments

- Grey and Brown lenses protect you from sun glare, UV rays and impact for outdoor use.

Your safety glasses should fit close to the face to minimise gaps. Find a style comfortable to wear.

Conclusion

It is important you chose the correct eyewear for you. It needs to be individually fitted because people find certain safety glasses more comfortable than others. The type of protect safety glasses you chose depends on the industry you work in. Make sure you maintain and store your safety eyewear correctly to maximise their shelf life.