Cut Resistant Gloves & Sleeves - How to Choose the Correct Protection Level

In 2016, new cut resistance ratings for anti-cut gloves and sleeves in the EN388:2016 standards were announced, and in 2019 these standards began to find their way into PPE product. You will likely be familiar with Cut 1 - 5 resistance levels, but these are now deprecated. The EN388:2016 cut proofing levels now range from Cut A to Cut F, with F being the highest cut protection available.

- Page Contents

- Old v New Standards

- Consider the Task

- Consider the Hazard

- Consider the Risk

- How to Work Out the Cut Resistance Level You Need

- Where to Buy Cut-Resistant Gloves and Sleeves

How Do The Old Cut Resistance Levels Correlate With The New Standards?

Simple answer: They don't.

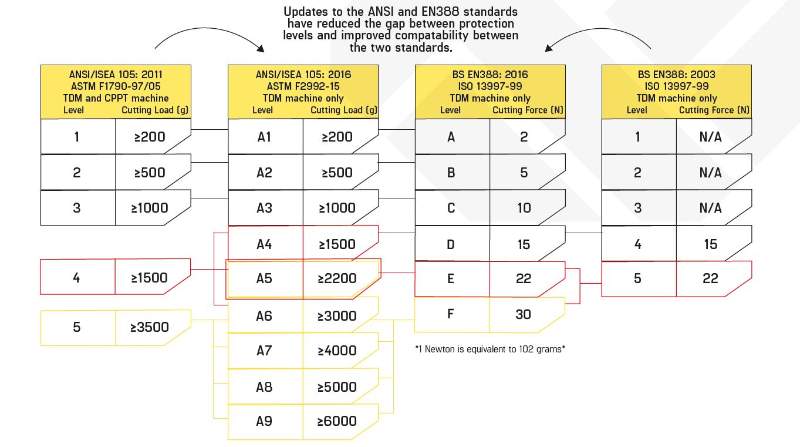

There is no direct correlation between the old 1-5 standards and the new A-F standards, so you should learn how to find the right glove cut protection level for your work hazards.

It is quite easy to figure this out - you can work out the correct cut protection level for gloves or cut sleeves with just 3 simple steps of identifying the Task, the Hazard and the Risk of injury, and doing some very simple maths.

Having said that, Cut Protection Safety Gloves manufacturer Tilsatec has provided us with this generalised comparison table:

Task - What Job Are You Doing?

Identify the work you are doing, how much dexterity is needed and where you are working.

Assess the type of work that is being done and decide how much dexterity/flexibility is needed. Review the conditions of the working environment.

Type of work

- Light duty: low wear and a relatively clean environment. High gauge material can be considered with palm coating

- Medium duty: variety of working conditions but still low wear

- Heavy duty: high wear, tough working conditions, dirty environment

Required Dexterity – Gloves Material

- Low: handling large bulky items – Leather Gloves, PVC. 7-gauge fabric

- Medium: handling smaller items that can be held in one hand – Polyester, Aramid. 10-gauge fabric

- High: handling very small items that can be held in the fingertips – Nylon, HPPE. 13 – 18-gauge fabric

There are a variety of different materials used to make gloves. Here are some examples of materials used as coatings by cut glove manufacturer Portwest for different working applications.

| Working Conditions | Coatings |

| Dry | PU, Latex, Nitrile (Foam, Sandy, Smooth) |

| Wet | Latex, PU, Nitrile (Foam, Sandy) |

| Oil & Grease | Nitrile (Foam, Sandy) |

| Chemical | Latex, Nitrile, PVC |

| Heat | Leather |

| Cold | All |

There are an infinite combination of tasks, work environments and individual requirements that to name a type of cut glove for each one would be impossible. The information above is to help you make a decision that works for you, but is not definitive.

Hazard - What Can Cause an Injury?

Identify what could cause injury and what is the level of control that you have.

Break the task down into 5 hazard factors and identify the level of control you have over the hazard.

| Hazard Identified | Hazard Factor |

| No Hazard | 1 |

| Fully Controlled Hazard | 2 |

| Controlled Measures | 3 |

| Limited Control | 4 |

| No Control | 5 |

If a chemical hazard is identified, then this becomes the principal hazard and should take priority over the cut resistance. Chemical protection can be complex so if you are unsure what protection to use please speak to a XAMAX® Sales Advisor on 01924 266668.

Thermal Hazards (Heat and Cold) should be assessed separately. Often a heat or cold hazard is the principal hazard. The requirement to protect against these thermal hazards will probably limit the range of cut-resistant gloves that you can choose from.

Risk - What is the likelihood of getting injured?

Identify the chances of injury whilst performing the task.

The risk of injury is split into 6 risk factors and should be quite self-explanatory.

| Risk of Injury | Risk Factor |

| No Perceived Risk | 1 |

| Very Low Risk | 2 |

| Low Risk | 3 |

| Medium Risk | 4 |

| High Risk | 5 |

| Very High Risk | 6 |

How To Work Out Cut Resistance Level

Once you complete a risk assessment for your tasks and have a Hazard Factor and a Risk Factor, you can use the Hazard x Risk calculation to help select the appropriate levels of cut resistance required from you cut gloves.

Multiplying the Risk by the Hazard will provide a performance level (value) from which to base the required cut resistance. The value used for the new test method is Newton’s, following this method will give an appropriate Newton value. Using the two tables above, calculate the required minimum cut performance. e.g. High Risk (5) x Limited Control (4) = 20

The table below explains the performance level of each cut level against the risk factors.

| Risk Factor | CUT PERFORMANCE (NEWTONS) = (RISK x HAZARD) | ||||

| 6 | 6 | 12 | 18 | 24 | 30 |

| 5 | 5 | 10 | 15 | 20 | 25 |

| 4 | 4 | 8 | 12 | 16 | 20 |

| 3 | 3 | 6 | 9 | 12 | 15 |

| 2 | 2 | 4 | 6 | 8 | 10 |

| 1 | 1 | 2 | 3 | 4 | 5 |

| Hazard Factor | 1 | 2 | 3 | 4 | 5 |

Now apply the performance level to the EN388:2016 levels below to find a suitable level of cut protection.

| Levels of Performance to EN388:2016 | ||||||

| Cut Protection Level | A | B | C | D | E | F |

| Cut Level in Newtons | 2 | 5 | 10 | 15 | 22 | 30 |

Cut resistant gloves are tested to a minimum performance level. If you are not sure of the required cut protection level you need, choose the next level up.

E.G. if your assessment suggests 16N then you should choose a level E glove, rather than drop down a level and risk safety.

Where to Buy Cut Resistant Gloves

There are many styles of cut resistant gloves and sleeves which suit most applications. XAMAX® are continually working with suppliers and manufacturers to bring new and improved cut resistant PPE to our offering.

Here are some of our best selling cut resistant gloves:

If you cannot find the level of protection you need, or are unsure as to what you really need, give us a ring - we'd be happy to help.