How did the Safety Footwear Regulations Change in 2022?

The safety footwear requirements were considerably updated in 2022, most notably in the EN ISO 20345:2022 and EN ISO 20347:2022 standards. These changes reflect major advances in ensuring worker safety across a variety of sectors. Understanding these developments is critical for employers, organisations, and individuals responsible for workplace safety to maintain compliance and protect employees' well-being.

This article will walk you through the important changes to safety footwear regulations, how they affect both employers and employees, and how to make sure your footwear meets the most recent standards.

- Page Contents

- Overview of the 2022 Safety Footwear Standards

- Types of Footwear Covered by the 2022 Standards

- Key UK Regulations for Safety Footwear

- Key Changes in EN ISO 20345:2022 and EN ISO 20347:2022

- New Markings and Marking Changes

- How to Ensure Compliance with the New Standards

- Applications by Industry

- Why Choose XAMAX® for Your Safety Footwear?

- Conclusion

Overview of the 2022 Safety Footwear Standards

The EN ISO 20345 and EN ISO 20347 standards are essential to establishing the minimum requirements for safety footwear. They encompass everything from protection features to testing regulations, ensuring that industrial footwear minimises worker injuries.

The EN ISO 20345:2022 standard is largely applicable to footwear designed to provide protection in high-risk areas (such as construction and engineering). EN ISO 20347:2022, on the other hand, focusses on occupational footwear in which high-level protection (such as toe caps) is optional but some protection (such as slip resistance) is necessary.

Here are the most significant modifications in these standards from the previous editions (EN ISO 20345:2011 and EN ISO 20347:2012):

Types of Footwear Covered by the 2022 Standards

- Safety Boots: Footwear designed for industries with a high risk of impact or compression injuries, such as construction, manufacturing, and mining.

- Safety Shoes: Typically used in lower-risk environments like warehousing, these offer toe protection and slip resistance.

- Safety Trainers: Lightweight footwear ideal for roles where mobility is key, such as in logistics or maintenance.

- Wellington Boots: Provide protection in wet or chemical-heavy environments like agriculture or fisheries, with resistance to liquids and chemicals.

Each type of footwear must meet specific EN ISO 20345:2022 or EN ISO 20347:2022 ratings depending on the work environment.

Key UK Regulations for Safety Footwear

Employers must provide personal protection equipment (PPE) such as safety footwear to employees who are exposed to health or safety dangers, according to UK legislation. Among these are the Personal Protective Equipment at Work Regulations of 1992, which align to European standards and stipulate that employers ensure that PPE is suitable, well-maintained, and provided at no charge when required.

With the 2022 updates, UK safety standards now reflect the following changes in PPE footwear:

Key Changes in EN ISO 20345:2022 and EN ISO 20347:2022

New Classification for Slip Resistance: The new standards provide enhanced guidelines for slip resistance, now a mandatory requirement for all certified footwear. Testing on both ceramic tiles (SRA) and steel plates with glycerol (SRB) is included to simulate various working environments. Footwear must pass tests for both to meet the SRC designation, which applies to all high-slip risk industries.

Breathability and Comfort: Worker comfort has been emphasised in the latest regulations. The EN ISO 20345:2022 standard includes improved guidelines on breathability, moisture management, and overall comfort, making long shifts in safety boots more manageable, reducing fatigue, and increasing worker productivity.

Impact Resistance of Toe Caps: Toe caps must still withstand a 200-Joule impact (equivalent to dropping a 20 kg weight from a height of 1 meter). However, composite toe caps (made from non-metal materials) are now more widely tested under varying temperatures, ensuring that safety boots perform equally well in extreme hot or cold conditions.

Penetration Resistance: Footwear must meet updated penetration resistance standards, ensuring that soles protect against sharp objects in industrial settings. Composite and steel midsole protections must undergo strict testing to prevent penetration by sharp objects like nails, glass, or debris on site. This is particularly relevant for construction and demolition industries.

Electrical and Anti-Static Properties: In high-risk sectors like electronics and energy, regulations for electrical resistance and anti-static properties have been tightened. The new standards now include more stringent tests to ensure footwear protects against electrostatic discharge (ESD) or electrical shocks.

Heat and Cold Resistance: The EN ISO 20345:2022 standard now provides more detailed guidelines on the HI (heat insulation) and CI (cold insulation) ratings, ensuring footwear can withstand a range of environmental conditions. This is especially relevant for industries such as welding, foundries, and outdoor work.

Sustainability and Materials: The 2022 standards emphasise sustainability, encouraging manufacturers to use eco-friendly and recyclable materials while maintaining high levels of protection. This focus is a reflection of the industry's drive towards more sustainable manufacturing practices.

New Markings and Marking Changes

With regulation changes comes new safety claims and new markings to suit the advancements in safety footwear technology:

| Icon | Description |

|---|---|

| FO (Fuel Oil Resistance): This marking indicates that the outsole material has been tested for resistance to fuel oils. This is no longer part of the Shortcut codes and must be marked separatley |

| P (Penetration Resistance) is now split across 3 codes: P - Perforation resistance metallic. Resistance to sole perforation of nails and sharp objects. Incorporating a metallic perforation resistant insert. PL - Perforation resistance non-metallic (LARGE). Resistance to perforation of nails. Incorporating a non-metallic Perforation resistant insert, tested with a 4.5mm test nail. For general end use where nails may be present. PS - Perforation resistance non-metallic (SMALL). Resistance to perforation of nails. Incorporating a non-metallic Perforation resistant insert, tested with a 3mm test nail. Intended for specialist uses where there is a higher likelyhood of encountering nails or likelyhood of encountering narrower nails. |

| C (Partially Conductive). The terminology has been changed from “Conductive”, to prevent confusion with claims associated with live electrical working. |

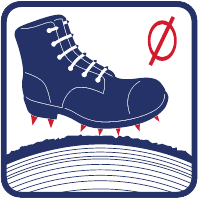

| SRA, SRB, SRC (Slip Resistance Ratings) are not mandatory. Slip resistance on tiled floor surface with Sodium Lauryl sulphate (soapy water) lubricant, tested at both the heel and forepart. No additional marking is applied. SR - Slip resistance on the tiled floor surface with glycerol lubricant, tested at both the heel and forepart. The steel floor surface is no longer used in testing. Ø - Slip resistance properties have not been achieved but the outsole includes specialist features such as spikes for logging or heavy cleats for use in soft and loose ground. |

| WPA (Water Resistance): Formerly "WRU" indicates that the footwear has water-resistant uppers, meaning the material used for the upper part of the footwear can resist water penetration. This feature is important for workers in wet or damp environments, such as those in outdoor construction or maintenance roles, where keeping the feet dry is critical to avoid discomfort and potential health risks such as trench foot. |

| LG - A new safety claim "ladder grip" indicates that the sole is designed with patterning in the waist area to conform to the rungs of a ladder. |

| SC - A new claim "Scuff cap" indicates that the footwear includes an additional overlay material in the toe area offering abrasion resistance during kneeling activities. |

How to Ensure Compliance with the New Standards

Employers should review their current stock of safety footwear and ensure that it complies with the EN ISO 20345:2022 or EN ISO 20347:2022 standards.

Footwear should be inspected regularly for wear and tear, and employees should be trained to understand the importance of choosing footwear based on the specific hazards they face on-site.

Applications by Industry

The updates to these standards are designed to address industry-specific risks:

- Construction: Focus on impact and penetration resistance, ensuring that all footwear meets S3 standards with toe cap protection and penetration resistance.

- Engineering: Higher standards for electrical resistance and protection against sharp objects, with composite and steel options now more rigorously tested.

- Logistics and Warehousing: Emphasis on slip resistance and lightweight comfort, with composite toe caps offering protection without the bulk of steel.

- Agriculture and Fisheries: Increased focus on waterproofing, chemical resistance, and thermal insulation to protect workers in wet environments.

Why Choose XAMAX® for Your Safety Footwear?

As a BSiF Registered Safety Supplier, XAMAX® ensures that every pair of safety footwear we supply complies with the latest UK and European standards. We pride ourselves on providing safety boots, shoes, and trainers that meet or exceed the EN ISO 20345:2022 and EN ISO 20347:2022 standards, so your team gets maximum protection in any work environment.

Whether you need steel toe caps for heavy industry or lightweight composite safety trainers for logistics, we have the perfect solution for your workforce.

Browse our range of compliant safety footwear or contact our team to discuss your PPE needs.

Conclusion

The 2022 updates to safety footwear regulations bring essential changes to protect workers across various industries.

By understanding the requirements of EN ISO 20345:2022 and EN ISO 20347:2022, you can ensure that your safety footwear meets the latest standards, providing maximum protection and comfort.

From improved slip resistance to more stringent electrical safety standards, these updates highlight the importance of choosing the right footwear for the job.

Stay compliant, protect your workers, and choose XAMAX® for all your safety footwear needs.